Interlining Technical Indicators: A Guide to Quality

The Unseen Details: A Guide to High-Quality Interlining’s Technical Indicators

Interlining Technical Indicators:In the competitive world of apparel manufacturing, what lies beneath the surface is just as important as the outer fabric. The quality of a garment’s interlining dictates its shape, feel, and longevity. While a low-cost interlining might seem like a good deal, a lack of robust technical specifications can lead to costly issues like bubbling, shrinking, and a short lifespan.

To ensure your garments maintain a professional finish over time, you must look beyond the price tag and evaluate the technical indicators of high-quality interlining.

The Core Metrics of Interlining Fabric

A great interlining begins with its foundational fabric. These are the key properties to consider:

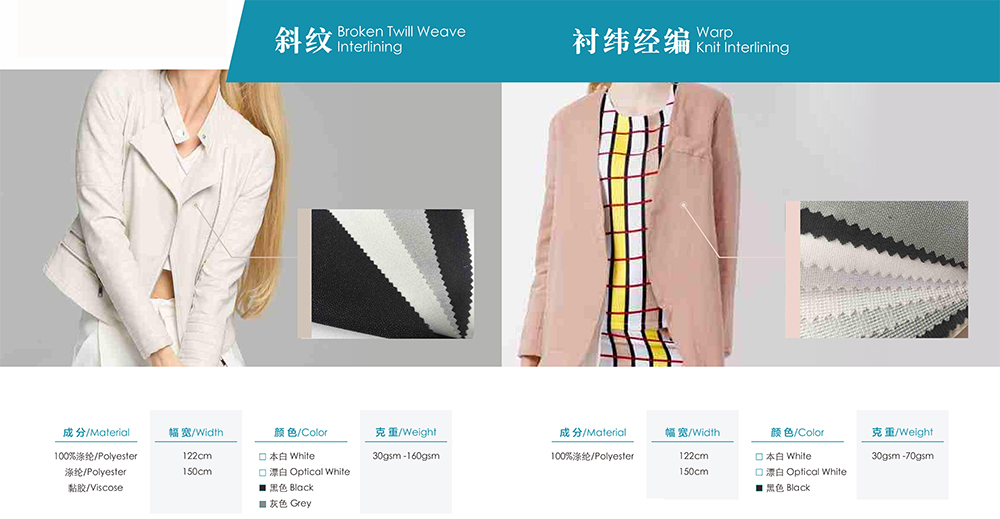

- Weight (GSM): Measured in grams per square meter (gsm), weight is a primary indicator of an interlining’s support level. A higher gsm provides more structure, ideal for tailored outerwear, while a lower gsm is best for lightweight blouses and dresses.

- Composition: The fibers used (e.g., polyester, cotton, wool, nylon) determine its hand feel, flexibility, and compatibility with the outer fabric. A blend often balances multiple desirable traits.

- Dimensional Stability: A high-quality interlining should not shrink or stretch excessively when exposed to heat and moisture. This stability is critical to prevent the interlining from deforming and causing the outer fabric to pucker after fusing.

Assessing the Adhesion and Fusion

The most critical function of a fusible interlining is its ability to bond securely to the outer fabric. The quality of this bond is determined by several factors:

- Resin Type: The type of adhesive resin (e.g., PA, PES, EVA) dictates its bonding strength and resistance to washing and dry cleaning. Choosing the right resin is crucial for ensuring the bond lasts.

- Coating Method: The way the adhesive is applied, whether in a uniform “paste” or a “dot” pattern, affects the final feel and breathability of the fused fabric.

- Peel Bond Strength: This is a measurable force required to separate the interlining from the outer fabric. A higher peel strength indicates a stronger, more reliable bond.

- Blistering Resistance: A good interlining should resist the formation of blisters or air pockets after fusing, ensuring a smooth, uniform surface.

Compatibility with the Outer Fabric

An interlining must work in harmony with the outer fabric to achieve the desired result.

- Hand Feel: The interlining’s feel should complement the outer fabric. For a soft garment, a soft interlining is a must to avoid a stiff, unnatural feel.

- Drape and Recovery: A quality interlining should maintain the fabric’s natural drape while adding support. For stretch fabrics, it should stretch and recover at a similar rate to prevent distortion.

Durability and Resilience

The best interlinings are engineered to withstand the rigors of everyday use and care.

- Tensile and Tear Strength: A strong interlining adds tear resistance to the garment, especially in high-stress areas like seams.

- Resistance to Washing and Dry Cleaning: The bond and fabric properties should remain intact after multiple washes and dry cleaning cycles, preventing bubbling or peeling over time.

- Anti-Puckering: A quality interlining should prevent the fabric from gathering or puckering at the seams, ensuring a consistently flat and polished finish.

The Role of Performance Testing

Reputable interlining suppliers don’t just make claims; they back them up with data. They use standardized tests (such as AATCC and ISO) to measure and verify a product’s performance in a controlled environment. This technical data is essential for making an informed choice before bulk production.

Innovations in Interlining

The industry is constantly evolving, with new technologies offering even better solutions:

- Eco-Friendly Materials: Many modern interlinings are made from recycled or sustainable materials, meeting the growing demand for environmentally conscious products.

- Specialized Functions: Innovations have led to interlinings with unique properties like antimicrobial protection, moisture-wicking capabilities, or enhanced thermal insulation.

In conclusion, the true mark of a high-quality interlining is its technical performance. By understanding these key indicators and working with a knowledgeable supplier, you can ensure your garments have the structural integrity and professional appearance that will stand the test of time.

FAQ

Q1: What is the main difference between fusible and non-fusible interlining? A: Fusible interlining has an adhesive on one side that bonds to the fabric with heat, while non-fusible interlining is sewn into the garment and requires no heat to apply.

Q2: How do I know which interlining to use for my fabric? A: The best practice is to match the interlining’s weight and hand feel to the outer fabric. A trustworthy supplier should provide technical data and samples to help you choose the right one.

Q3: Can I use the same interlining for all my projects? A: No, different projects require different types. A heavy, structured garment needs a different interlining than a lightweight, drapey blouse to achieve the desired result.

Q4: What is the most common reason for interlining to bubble or peel? A: This is usually a sign of an incorrect fusing process. Common causes include a low iron temperature, not enough pressure, or using steam when you should use a dry iron.

continue reading

Related Posts

This article explains fusing interlining, how it works, common types, applications, and practical tips for proper fusing.

This article gives a full overview of interlining, including coating types, product categories, structures, features, and common uses.

This article explains nonwoven fusible interlining, its features, uses, and how to choose the right type for garments.

.png)