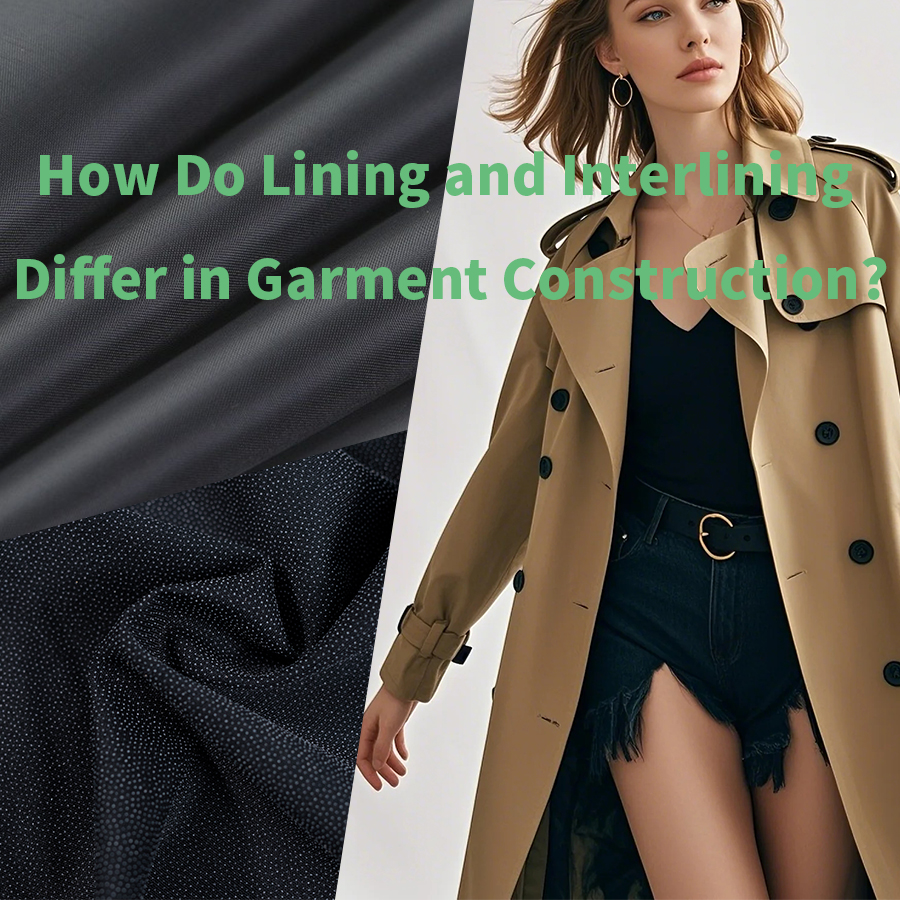

How Do Lining and Interlining Differ in Garment Construction?

What’s the Difference Between Lining and Interlining?

In garment and tailoring parlance, “lining” and “interlining” are two terms often used interchangeably by non-specialists—but in fact they serve very different functions. This article explains their definitions, contrasting roles, material types, methods of attachment, and tips for garment makers and consumers alike.

What Is a Lining?

-

Definition & Purpose

A lining is a layer of fabric sewn into the interior of a garment to cover seams, hide structure, and provide a smooth finish against the body. 维基百科+2Mood Fabrics+2 -

Materials & Features

Linings are typically made from lightweight, smooth fabrics such as silk, polyester, rayon, or acetate. Their surface often has a slippery or soft hand to allow ease of movement and minimize friction. -

Functions

-

Aesthetic finish — conceals stitches, interfacings, and inner structure

-

Comfort & wearability — prevents rough outer fabrics from irritating skin

-

Ease of wearing — helps garments slide on/off smoothly

-

Protects outer fabric from sweat, abrasion, and wear

-

-

Attachment Method

Linings are usually sewn into the garment shell at hems, facings, hems, or waistbands. They are not typically fused with adhesives.

What Is an Interlining?

-

Definition & Purpose

Interlining is a hidden fabric inserted between the main (outer) fabric and the lining (or sometimes between two layers of shell fabric) to provide structure, shape, reinforcement, or insulation. -

Material & Types

Interlinings may be woven, non-woven, knitted, or composite. They may be fusible (with an adhesive layer) or sew-in (nonfusible). Fibers used include cotton, polyester, nylon, viscose, and blends. -

Functions

-

Support & stiffness — helps collars, lapels, cuffs, waistbands hold shape

-

Shape retention — prevents distortions or sagging over time

-

Reinforcement — strengthens weaker fabrics in stress zones

-

Thermal insulation — in certain garments (e.g. coats) interlining adds warmth

-

-

Attachment Method

Interlinings can be sewn in (nonfusible) or fused (heat, pressure, adhesive) to the main fabric.

Key Differences: Lining vs Interlining

Here’s a side-by-side comparison to clarify:

| Feature | Lining | Interlining |

|---|---|---|

| Placement | On the inner surface of garment (next to skin) | Sandwiched between outer fabric and lining (or between layers) |

| Purpose / Role | Conceal inner construction, improve comfort, aesthetic finish | Add structure, support, shape, reinforcement, sometimes warmth |

| Material Weight / Feel | Lightweight, smooth, often silky | Can be light to medium weight, depending on support needed |

| Attachment Method | Sewn | Sewn or fused with adhesives & heat |

| Visibility | May be visible when garment is unbuttoned/open | Invisible in the finished garment |

| Replaceability | Easier to remove or repair | Usually not easily removable once fused/sewn |

| Common Applications | Jackets, coats, skirts, dresses, trousers | Collars, cuffs, waistbands, fronts of jackets/coats, structured parts |

Why Understanding the Difference Matters

-

Proper Component Selection

Picking the wrong material (e.g. using heavy interlining as lining) can cause stiffness, bulk, or discomfort. -

Processing Considerations

Fusible interlining requires controlled heat/pressure/time, whereas linings only need sewing. Mixing them incorrectly can lead to defects like bubbling or delamination. -

Garment Performance and Longevity

The correct interlining supports areas under stress. The lining protects and finishes. Misuse or poor matching may lead to deformation, peeling, or premature wear. -

Consumer Perception & Quality

Well-constructed garments with balanced lining and interlining offer better hand feel, tailored structure, and longevity. Consumers can often judge quality by how smooth and natural the interior feels and how well edges and structured parts hold.

FAQ (Frequently Asked Questions)

Q: Can lining act as interlining?

A: In some simple garments or light applications, a slightly heavier lining might provide modest support. But for structured parts like collars and cuffs, dedicated interlining is usually necessary.

Q: Is fusible interlining always better than sew-in?

A: Not always. Fusible interlining is convenient and efficient, but if adhesives or bonding parameters aren’t well matched, problems like bubbling, stiffness, or bond failure may occur.

Q: Does interlining add bulk to garments?

A: It can, especially if the interlining is thick or heavy. Good design balances structural support with minimal added weight and bulk.

Q: How can a consumer tell if interlining is good quality?

A: Inspect areas like lapels, collar, cuffs — they should keep shape and feel smooth inside. No puckering, bubbling, or rough patches should be visible.

Why Choose Shanghai Uneed Textile Co., Ltd.?

At Shanghai Uneed Textile Co., Ltd., we have deep expertise in both lining and interlining solutions, ensuring garments perform beautifully from the inside out:

-

Diverse Product Portfolio — we supply high-quality linings and interlinings tailored for different garment parts and functions.

-

Adhesive & Bonding Technology — our fusible interlinings use optimized adhesives matched to fabric types for reliable bonding.

-

Material Matching Expertise — we guide clients in pairing fabrics, interlinings, and linings to prevent defects like delamination or stiffness.

-

Rigorous Testing & QC — all our materials undergo inspection including bonding trials, shrinkage testing, and wear simulation.

-

Customer Support & Custom Solutions — we help clients with technical advice, sample trials, and troubleshooting to ensure final garment quality.

continue reading

Related Posts

This article explains fusing interlining, how it works, common types, applications, and practical tips for proper fusing.

This article gives a full overview of interlining, including coating types, product categories, structures, features, and common uses.

This article explains nonwoven fusible interlining, its features, uses, and how to choose the right type for garments.

.png)