How to Choose the Right Adhesive Type for Fusible Interlining?

How to Choose the Right Adhesive Type for Fusible Interlining?

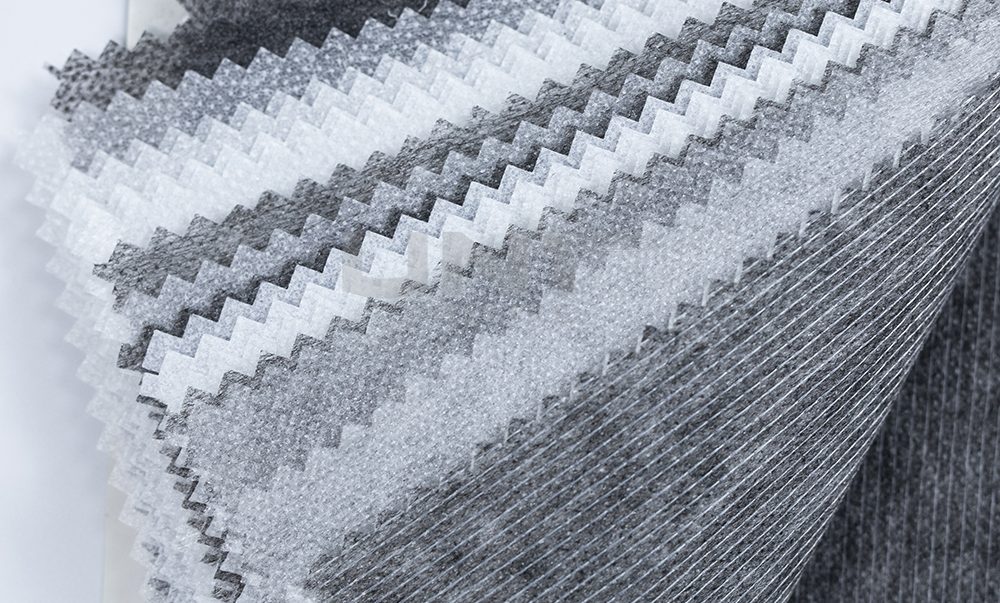

Fusible interlining is an essential component in modern garment manufacturing, providing structure, stability, and durability. Its effectiveness, however, largely depends on the adhesive layer (known as the “colloid” or “gum”) that bonds it to the fabric. Selecting the correct adhesive type is crucial for ensuring the quality and longevity of the final garment. This article will delve into the properties of different adhesive materials and provide a practical guide to help you make an informed decision.Adhesive Type for Fusible Interlining

Understanding the Core: Common Interlining Adhesive Types

The adhesive layer on fusible interlining is typically made of high-molecular-weight polymers that melt under specific temperature and pressure, penetrating and securely bonding to the fabric fibers. The most common adhesive types on the market include:

- Polyethylene (PE): Characterized by a low melting point, PE is ideal for heat-sensitive, lightweight fabrics like silk and chiffon. It provides a soft yet stable bond, preventing the fabric from being damaged or discolored by high temperatures.

- Polyamide (PA): Known for its strong adhesive bond and excellent resistance to both enzyme washing and Dry cleaning. This makes it the preferred choice for garments that require high durability and frequent laundering, such as workwear, uniforms, and items made from heavy fabrics.

- Polyester (PES): A versatile adhesive with a moderate melting point, PES offers a good balance of bonding strength and durability. It is particularly effective for synthetic fabrics like polyester and nylon due to its high chemical compatibility, creating a lasting bond. PES is also known for its good water wash resistance.

- Polyurethane (PU): Flexibility is PU’s main advantage. It is specifically designed for stretch fabrics (like spandex blends) and can stretch and contract with the fabric without compromising its original elasticity. PU interlining is an excellent choice for sportswear, activewear, or any garment that requires good stretchability.

Thermal Bond Nonwoven Interlining

Key Factors to Consider When Choosing an Adhesive

When selecting the most suitable adhesive type, you need to consider a combination of factors. Overlooking any of these can lead to a poor bonding effect and compromise the quality of the final product.

- Fabric Characteristics: This is the primary factor. The fabric’s material (natural vs. synthetic fibers), weight, texture, and any special finishes will all influence the adhesive choice. For instance, rough or porous fabrics may require an adhesive with a stronger bonding force.

- Bond Strength and Hand Feel: Do you want a soft and natural bond or a firm and durable one? Different adhesives provide varying degrees of stiffness and bonding strength, which directly impact the garment’s hand feel.

- Intended Use and Care Requirements: The garment’s purpose (casual wear, formal wear, sportswear) dictates its durability needs. For example, outdoor workwear requires an adhesive that can withstand repeated washing, while a one-time-use dress may have lower durability requirements. You also need to confirm if the adhesive can withstand daily care routines like washing, dry cleaning, or ironing.

- Heat Pressing Conditions: Each adhesive has specific melting points and pressing parameters. You must ensure the chosen adhesive’s melting point is compatible with the fabric’s heat tolerance and can achieve optimal bonding under your factory’s heat pressing equipment.

- Environmental and Climatic Factors: In certain high-humidity or extreme-temperature environments, the adhesive’s performance can be affected. Considering these factors helps prevent unexpected issues during production or use.

Avoiding Common Selection Mistakes

To ensure success, it is vital to avoid the following common pitfalls:

- Relying Solely on Experience: Over-relying on past experience can lead to overlooking the unique requirements of new fabrics or adhesives.

- Skipping the Testing Phase: Always conduct small-scale sample tests on the fabric and interlining before mass production. This is the best way to identify potential issues, adjust parameters, and confirm the desired outcome.

- Ignoring the Garment’s Final Function: Using interlining meant for casual wear on workwear, or for non-stretch fabrics on stretch fabrics, is inappropriate and will lead to poor results.

- Overly Focusing on Low Prices: While cost is an important consideration, sacrificing adhesive quality to save money can lead to product returns or customer complaints, making it a costly mistake in the long run.

Conclusion

Choosing the right adhesive for fusible interlining is a meticulous and professional task. By deeply understanding the properties of different adhesives and comprehensively evaluating key factors such as fabric type, required bond strength, final use, and heat pressing conditions, you can make the best choice. Remember, thorough sample testing and communication with professional suppliers are the golden rules for ensuring product quality and avoiding potential problems.

continue reading

Related Posts

This article explains fusing interlining, how it works, common types, applications, and practical tips for proper fusing.

This article gives a full overview of interlining, including coating types, product categories, structures, features, and common uses.

This article explains nonwoven fusible interlining, its features, uses, and how to choose the right type for garments.

.png)