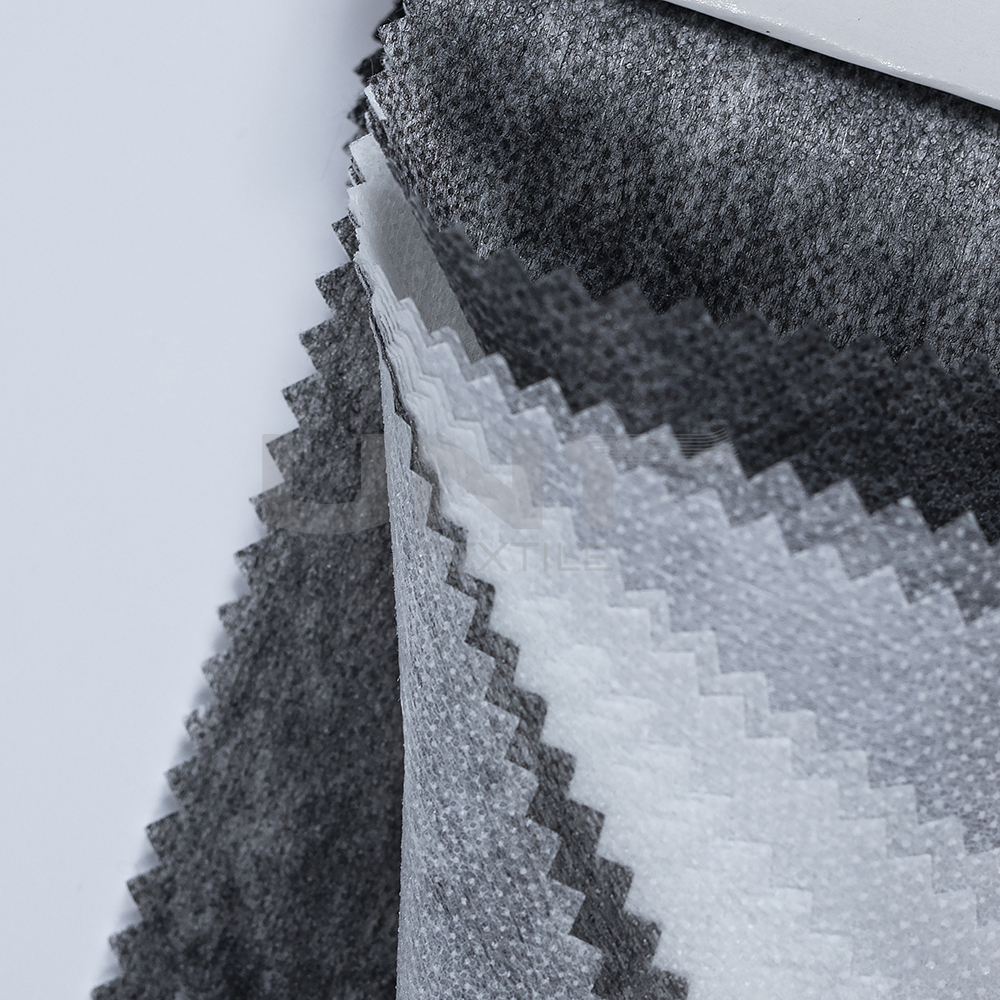

Premium Non-Woven Interlining Solutions

In the dynamic world of textiles and apparel, the secret to creating truly exceptional finished products often lies in a hidden, yet essential, component: non-woven interlining. At UNT, we have perfected this fundamental material to empower your designs with unparalleled durability, flexibility, and precision.

Discover why leading brands rely on our non-woven interlining to transform their creations from good to great. Unlike older, traditional alternatives, our innovative material provides a robust yet lightweight foundation, enhancing structure without ever compromising on comfort. Our unique bonded fiber technology ensures consistent, reliable performance for a wide range of applications, from reinforcing collars and cuffs to stabilizing intricate embroidery. With UNT, you can avoid the common pitfalls of inferior materials, such as bubbling, shrinkage, or stiffness.

5 Reasons to Partner with UNT for Non-Woven Interlining

- Engineered for Excellence: Our interlinings are crafted using advanced thermal-bonding technology, guaranteeing uniform density and superior adhesion. Say goodbye to uneven layers and fabric distortion.

- Commitment to Sustainability: For us, sustainability is more than just a phrase; it’s our core belief. Our materials are made with recycled fibers and low-energy processes, aligning perfectly with global eco-standards.

- Endless Versatility: Our extensive product range can handle it all, from featherweight fusible options for delicate silks to heavy-duty variants for industrial applications. Whatever your needs, we have a solution.

- Resistant to Heat and Washing: Engineered to withstand high-temperature ironing and repeated laundering, our interlinings ensure your garments maintain their integrity season after season.

- Cost-Effective Solutions: Our materials are easy to cut and apply, which helps you reduce waste and streamline your labor costs.

We are more than a supplier; we are your partner in elevating product quality and strengthening your brand legacy. Our team combines in-depth research and development with extensive industry knowledge to provide tailored solutions.

We invite you to experience the difference. Request a free sample kit, download a technical guide, or contact one of our specialists for a customized solution today.www.uneed-tex.com

continue reading

Related Posts

This article explains fusing interlining, how it works, common types, applications, and practical tips for proper fusing.

This article gives a full overview of interlining, including coating types, product categories, structures, features, and common uses.

This article explains nonwoven fusible interlining, its features, uses, and how to choose the right type for garments.

.png)