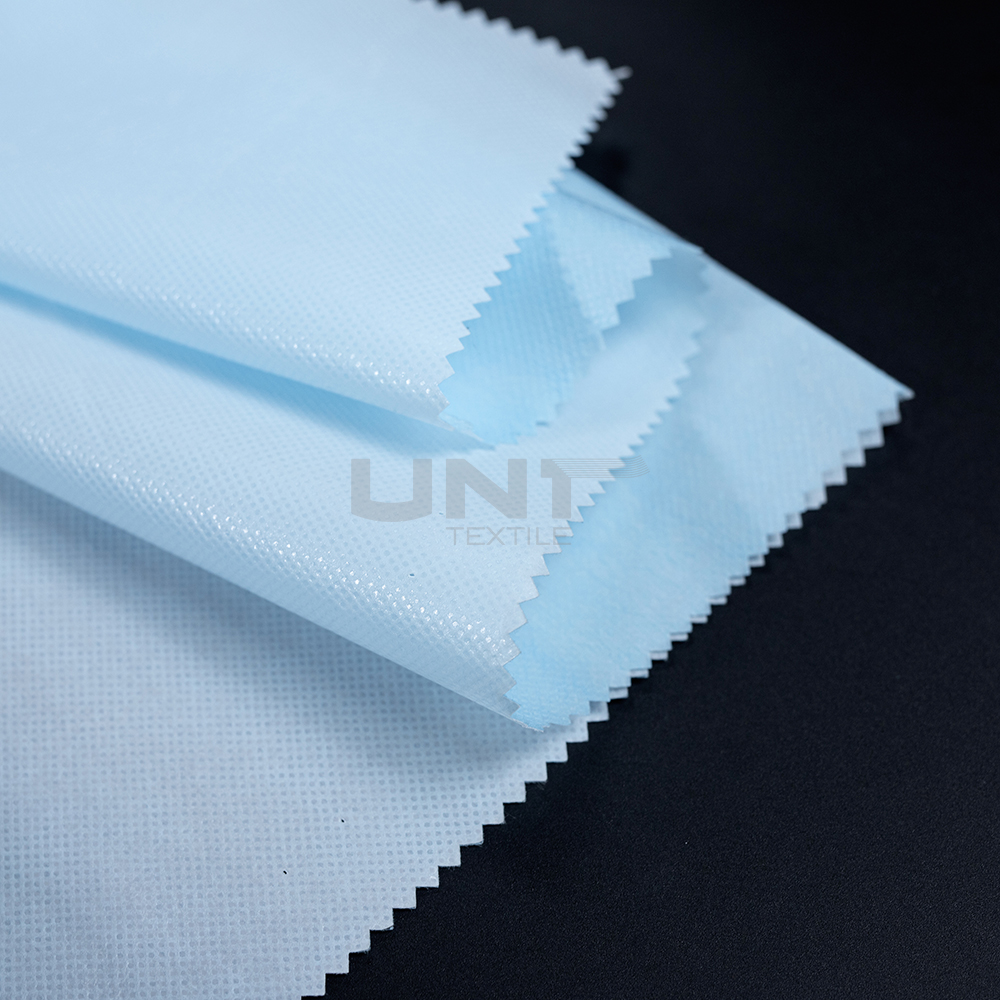

Composite Nonwoven Fabric

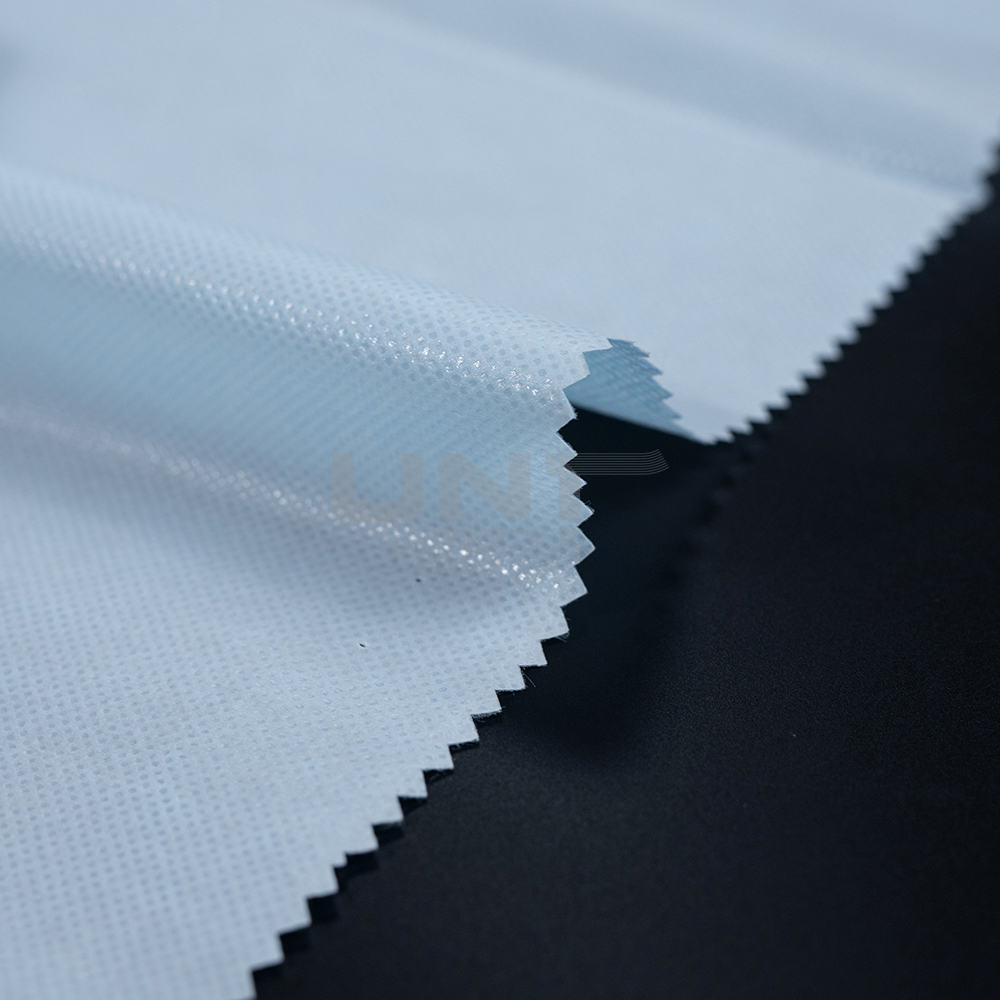

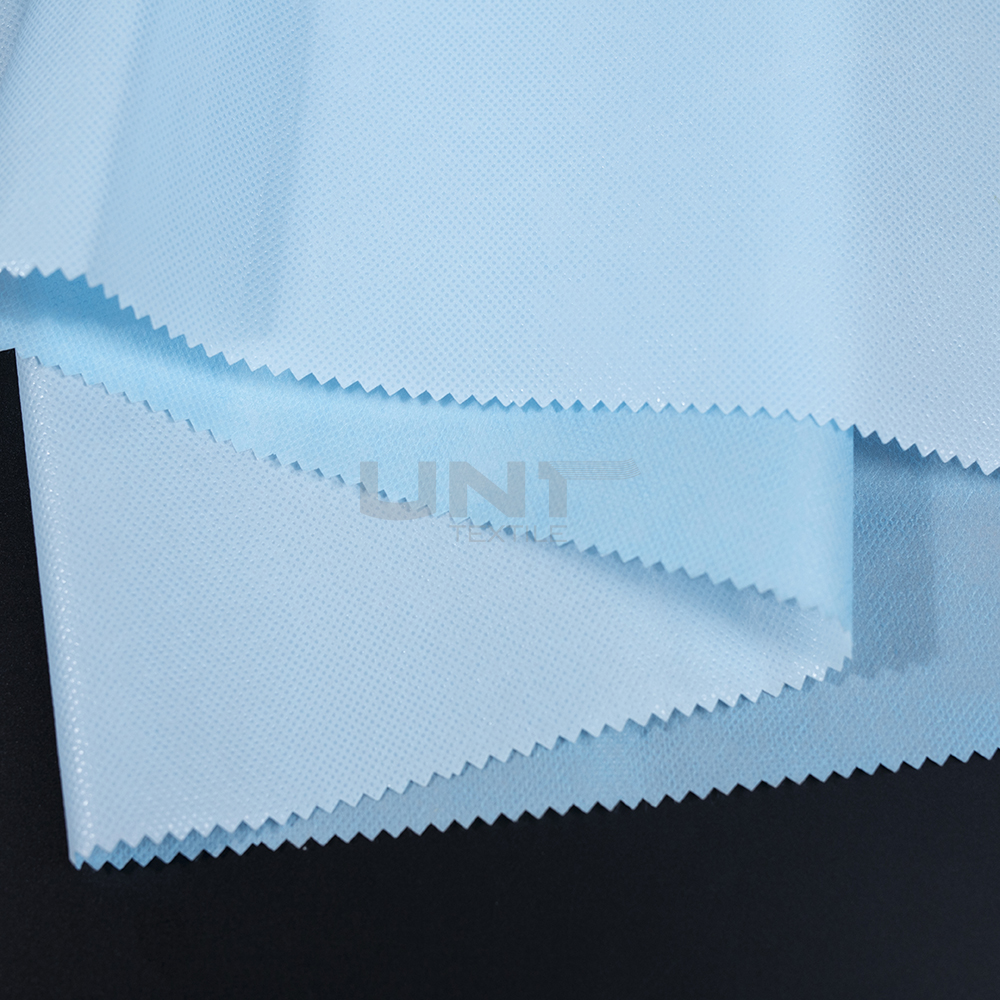

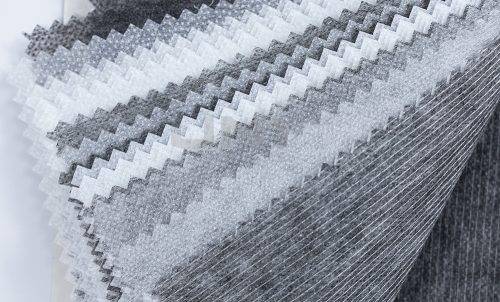

Composite Nonwoven Fabric is where innovation meets versatility. We create it by laminating or coating nonwoven fabrics with materials like breathable films, aluminum layers, or other specialized components, using advanced technologies such as glue spraying, ultrasonic bonding, and PE coating.

You’ll find our composites available in both SF (Nonwoven Fabric + Breathable Film) and SFS (Nonwoven Fabric + Breathable Film + Nonwoven Fabric) series. These engineered fabrics deliver superior physical strength, excellent water barrier properties, and impressive hydrostatic head performance.

This makes them incredibly valuable across medical, hygiene, industrial, and automotive sectors, where they’re widely applied for things like protective clothing, highly absorbent materials, and much more.

product introduce

Composite Nonwoven Fabric Product Highlights:

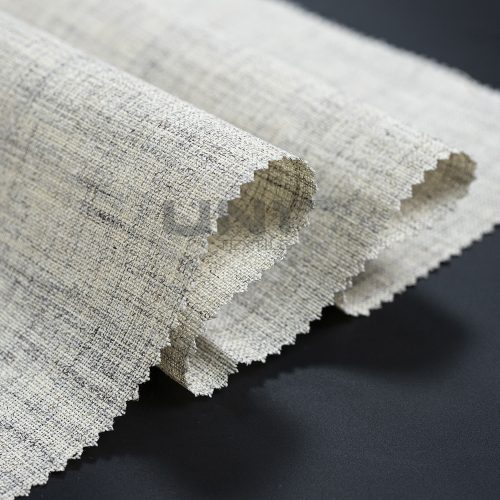

- Flexible Composition: We offer versatile combinations, including nonwoven fabric paired with PE film, aluminum film, spunlace, or meltblown materials, ensuring we meet diverse application needs.

- Superior Performance: Expect excellent water resistance, ideal air permeability, and high tensile strength, guaranteeing reliability across all your applications.

- Advanced Manufacturing: Our fabrics are created using innovative ultrasonic bonding and advanced coating processes, which means seamless integration and impressive durability.

- Broad Applications: These composites are perfect for medical absorbent materials, hygiene products, automotive insulation, and various industrial protective gear.

additional information

| Minimum Order Quantity | 500kg per type |

|---|---|

| Certification | OEKO-TEX, GRS, SGS |

| Price Range | USD $1.5 – $2.5/kg (Depending on material and weight) |

| Packaging | Roll packed in PE plastic bags, with an outer strong woven polybag |

| Transportation | Via sea, air, or express logistics |

| Payment Terms | L/C, D/P, T/T, Western Union, PayPal |

| Delivery Time | 7-15 days based on order size |

| Monthly Production Capacity | 2,000,000 meters |

| Roll Length | 100m-1000m/roll |

| Special Customization | Available for color, weight, and width upon request |

Composite Nonwoven Fabric Product Specifications

| Product Series | Description | Material | Applications |

| SF | Non Woven Fabric + Breathable Film | Non Woven Fabric + PE Film | Medical |

| SFS | Non Woven Fabric + Breathable Film + Non Woven Fabric | Non Woven Fabric + Aluminum Film | Hygiene |

| Non Woven Fabric + Spunlace Non Woven Fabric | Protective | ||

| Non Woven Fabric + Meltblown Fabric + Non Woven Fabric | Industrial | ||

| Non Woven Fabric + PE Film + Non Woven Fabric | Automotive | ||

| Spunlace Non Woven Fabric + Breathable Film + Non Woven Fabric | |||

| Non Woven Fabric + Thermal Insulation Material + Aluminum Film | |||

| Aluminum Film + Thermal Insulation Material + Non Woven Fabric – Ultrasonic Composite | |||

| Non Woven Fabric + Breathable Film + Non Woven Fabric – Ultrasonic Composite | |||

| Medical Absorbent Material: PE Film + Absorbent Material | |||

| Medical Absorbent Material: PE Film + Hydrophilic Nonwoven or Spunlace Non Woven Fabric |

Related Products

Stay Ahead With UNT Updates

This article reviews ten reliable interlining manufacturers and highlights what buyers should look for when choosing a supplier.

This article explains fusing interlining, how it works, common types, applications, and practical tips for proper fusing.

This article gives a full overview of interlining, including coating types, product categories, structures, features, and common uses.

.png)