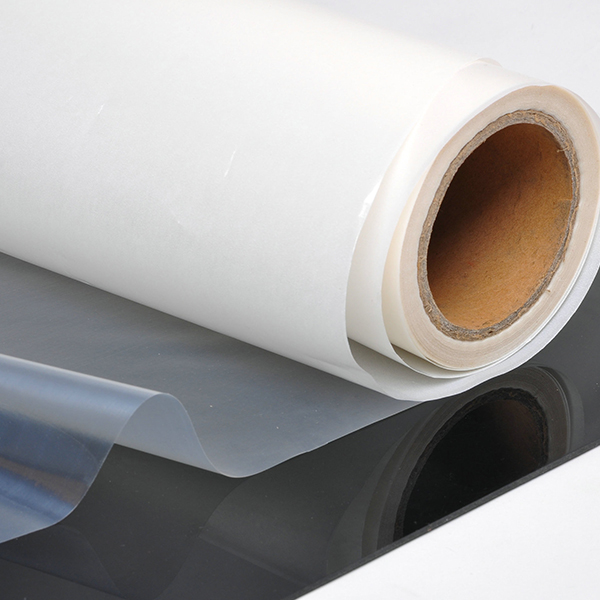

Hot Melt Adhesive Film

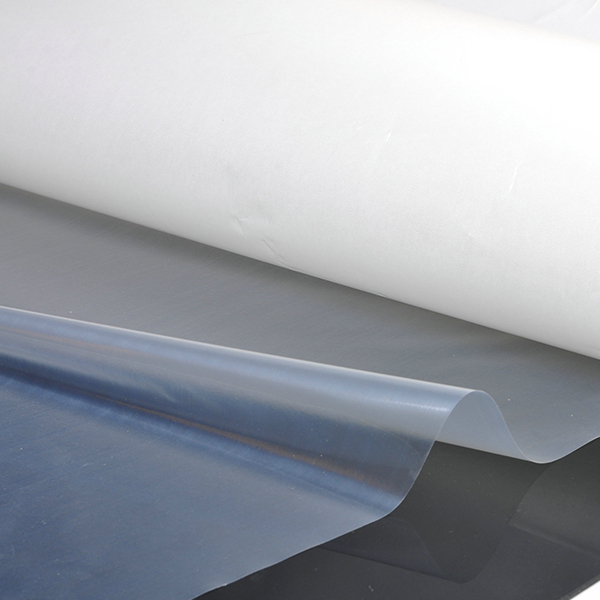

Our hot melt adhesive film is a versatile, high-performance bonding material available in materials like PO, PES, PA, EVA, and TPU. Its strong adhesion, excellent durability, and reliable heat-sealing properties make it an ideal choice for textiles, nonwoven fabrics, leather, and a variety of other garment components.

Widely used for everything from clothing to industrial applications, this film offers precise and efficient solutions for a diverse range of bonding needs.

product introduce

Hot Melt Adhesive Film Product Highlights:

- Multiple Materials: We offer a range of materials (PO, PES, PA, EVA, TPU) to perfectly suit different bonding requirements and applications.

- Strong & Durable Adhesion: Our film ensures a durable bond for textiles, leather, nonwoven fabrics, and more, thanks to its powerful adhesion.

- High Resistance: It’s highly resistant to both heat and water, providing reliable, long-lasting performance even in demanding environments.

- Eco-Friendly & Customizable: This film is eco-friendly and can be customized, making it a great solution for a wide range of garment and industrial uses.

additional information

| Minimum Order Quantity | 500kg per type |

|---|---|

| Certification | OEKO-TEX, GRS, SGS |

| Price Range | USD $1.5 – $2.5/kg (Depending on material and weight) |

| Packaging | Roll packed in PE plastic bags, with an outer strong woven polybag. |

| Transportation | Via sea, air, or express logistics. |

| Payment Terms | L/C, D/P, T/T, Western Union, PayPal |

| Delivery Time | 7-15 days based on order size |

| Monthly Production Capacity | 2,000,0000 meters |

| Roll Length | 100m-1000m/roll |

| Special Customization | Available for color, weight, and width upon request. |

Hot Melt Adhesive Film Product Specifications

| Material | Series | Thickness (mm) | Width (cm) | Melting Point (°C) | Heating Press Temp. (°C) | Pressing Time (s) | Pressure (kgf/cm²) | Water Resistance | Dry Cleaning Resistance | Bonding Strength (N/2.5cm) |

| PA | FFA-L | 0.02-0.20 | 0.5-160 | 105-110 | 115-125 | 15-20 | 0.3-0.5 | Good | Excellent | >20 |

| PA | FFA-H | 0.02-0.20 | 0.5-160 | 125-135 | 105-110 | 15-20 | 0.3-0.5 | Excellent | Excellent | >20 |

| PA | FFS-L | 0.02-0.20 | 0.5-160 | 65 | 80-100 | 15-20 | 0.3-0.5 | Good | X | >10 |

| PA | FFS | 0.02-0.20 | 0.5-160 | 85 | 110-130 | 15-20 | 0.3-0.5 | Good | X | >10 |

| PES | FFS-M | 0.02-0.20 | 0.5-160 | 115-120 | 120-130 | 15-20 | 0.3-0.5 | Good | X | >10 |

| PES | FWS-MH | 0.02-0.20 | 0.5-160 | 120-130 | 130-140 | 15-20 | 0.3-0.5 | Good | X | >10 |

| PES | FWS-H | 0.02-0.20 | 0.5-160 | 150-160 | 160-170 | 15-20 | 0.3-0.5 | Good | X | >10 |

| PO | FFO | 0.02-0.20 | 0.5-160 | 80-90 | 130-150 | 15-20 | 0.3-0.5 | Excellent | X | >10 |

| TPU | FFU | 0.02-0.20 | 0.5-160 | 65 | 85-110 | 15-20 | 0.3-0.5 | Good | Excellent | >15 |

| TPU | FFU-M | 0.02-0.20 | 0.5-160 | 110 | 135-145 | 15-20 | 0.3-0.5 | Good | Excellent | >15 |

| EVA | FFE-L | 0.02-0.20 | 0.5-160 | 65 | 80-90 | 15-20 | 0.3-0.5 | Good | X | >5 |

| EVA | FFE | 0.02-0.20 | 0.5-160 | 85 | 110-120 | 15-20 | 0.3-0.5 | Good | X | >5 |

Related Products

Stay Ahead With UNT Updates

This article explains fusing interlining, how it works, common types, applications, and practical tips for proper fusing.

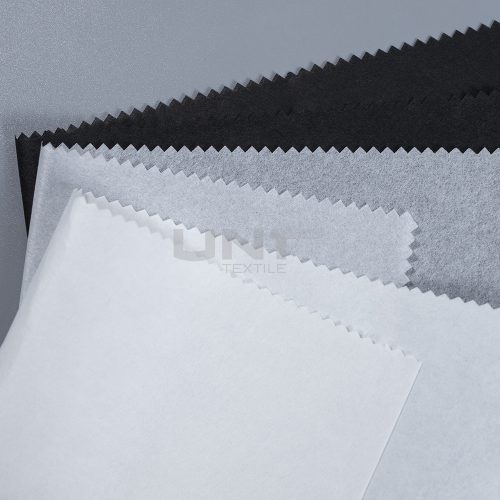

This article gives a full overview of interlining, including coating types, product categories, structures, features, and common uses.

This article explains woven fusible interlining, how it works, where it’s used, and how to choose the right one.

.png)