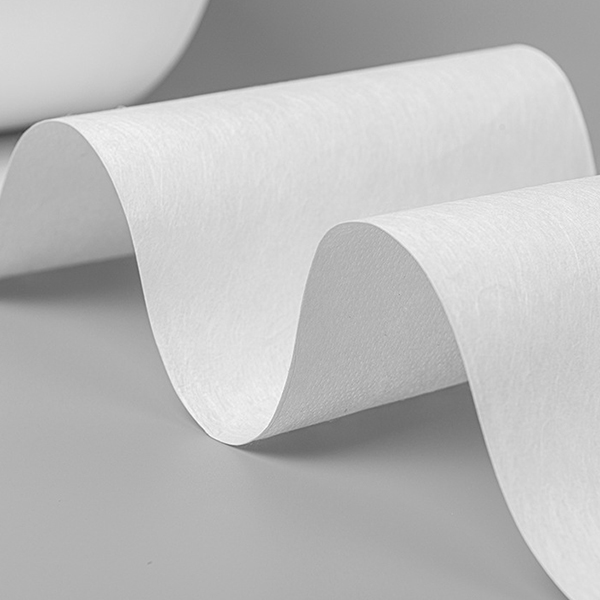

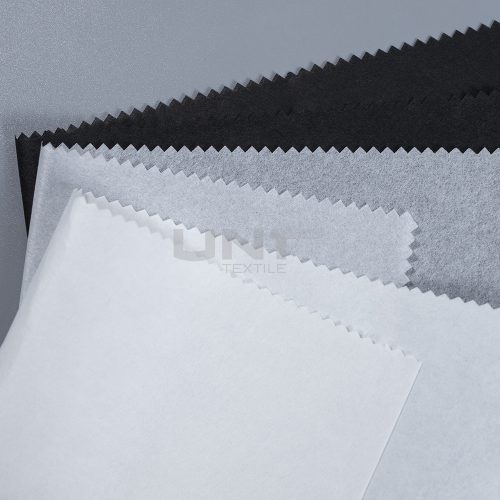

Meltblown Nonwoven Fabric

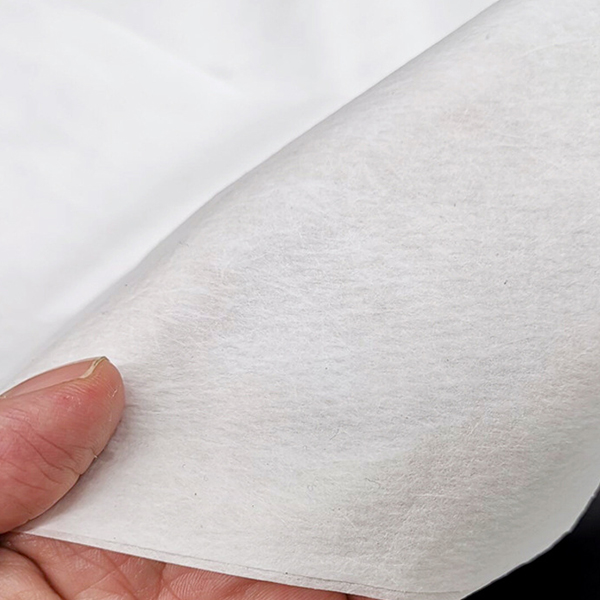

Our meltblown nonwoven fabric is crafted using advanced meltblown technology, with 100% polypropylene as its primary material. This process results in a remarkably fine fiber structure, giving it exceptional filtration, insulation, and adsorption properties.

Available in a versatile weight range of 20-100 gsm, you’ll find it widely used in critical applications like medical masks, advanced air and liquid filtration systems, efficient oil absorption, reliable thermal insulation, and various hygiene products.

This fabric is not only lightweight and breathable but also ensures high efficiency across a wide range of industrial and healthcare needs.

product introduce

Meltblown Nonwoven Fabric Product Highlights:

1.High Filtration Efficiency: Ultra-fine fiber structure ensures superior filtration performance, making it ideal for medical masks and air filtration systems.

2.Versatile Applications: Applicable in industries like healthcare, environmental protection, thermal insulation, and hygiene, addressing diverse needs.

3.Exceptional Material Properties: Manufactured with 100% polypropylene, offering lightweight, breathable, and eco-friendly characteristics.

4.Wide Range of Uses: Perfect for producing surgical masks, HEPA filters, oil absorbents, and insulation materials, meeting global quality standards.

additional information

| Weight | 25-100 gsm |

|---|---|

| Width | 160 cm / 240 cm / 320 cm |

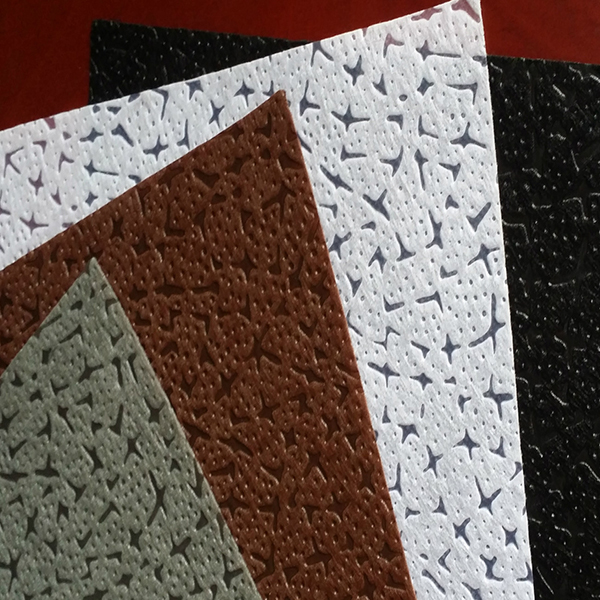

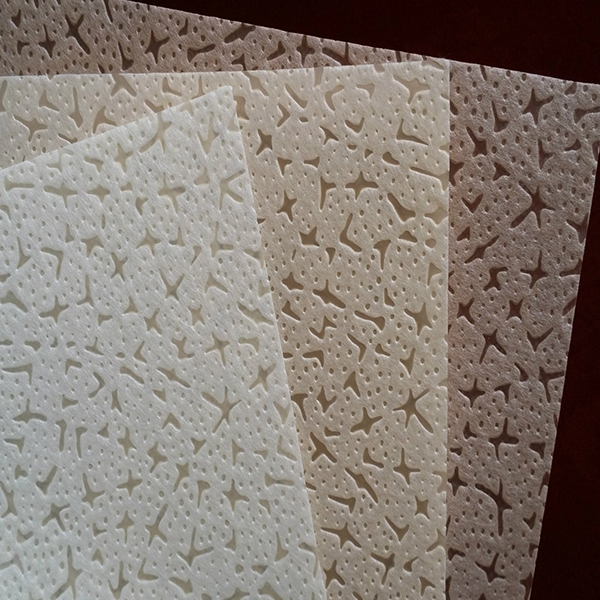

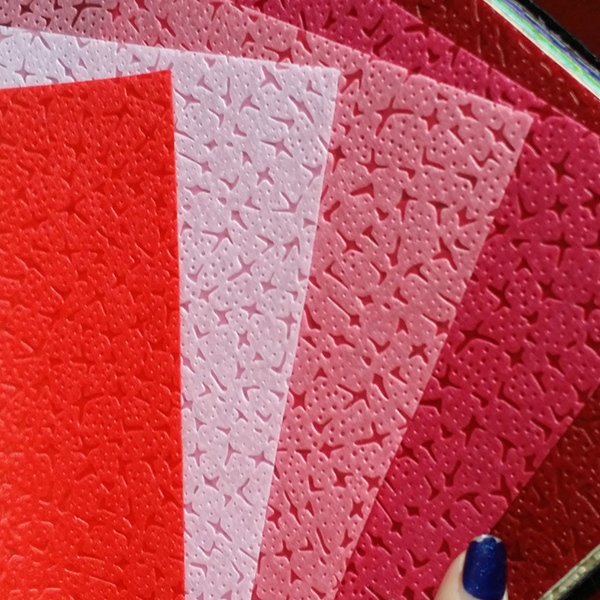

| Color | Customize |

| Pattern | Stripe, Chicken Paw Print, Plum, Others |

| Grade | BFE95, BFE99, PFE90, PFE95, PFE99 |

| Paraffin Oil Test | 80, 94, 99 |

| Standard | YY/T 0969, YY 0469, GB2626, KN90, KN95, KN99, KP90, KP95, KP99, GB 19083, GB/T 32610, EN149 FFP1, FFP2, FFP3, EN14683 Type I, Type II, Type IIR, KF94, N95, N99, ASTM F2100 Level 1, Level 2, Level 3 |

| Minimum Order Quantity | 500kg per type |

| Certification | OEKO-TEX, GRS, SGS |

| Price Range | USD $1.5 – $2.5/kg (Depending on material and weight) |

| Packaging | Roll packed in PE plastic bags, with an outer strong woven polybag. |

| Transportation | Via sea, air, or express logistics. |

| Payment Terms | L/C, D/P, T/T, Western Union, PayPal |

| Delivery Time | 7-15 days based on order size |

| Monthly Production Capacity | 2,000,0000 meters |

| Roll Length | 100m-1000m/roll |

| Special Customization | Available for color, weight, and width upon request. |

Related Products

Stay Ahead With UNT Updates

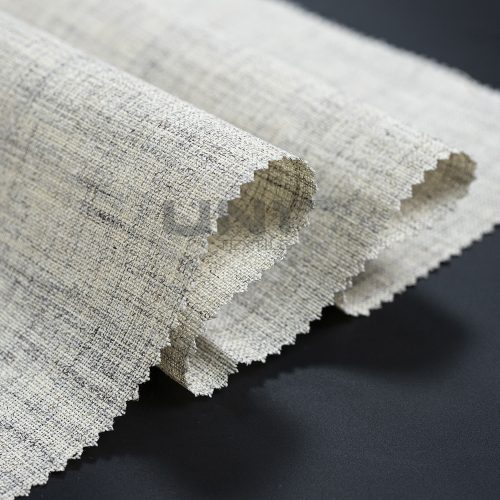

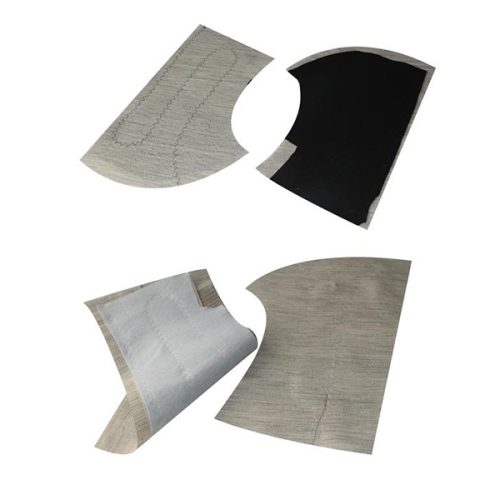

This article explains fusing interlining, how it works, common types, applications, and practical tips for proper fusing.

This article gives a full overview of interlining, including coating types, product categories, structures, features, and common uses.

This article explains woven fusible interlining, how it works, where it’s used, and how to choose the right one.

.png)