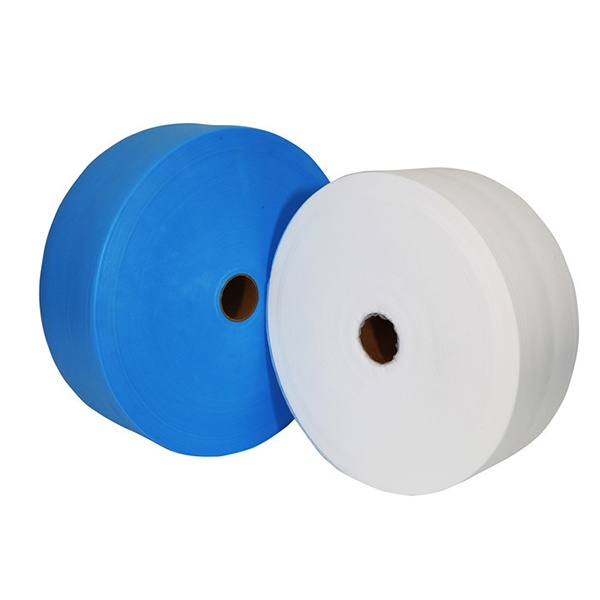

Spunlace Nonwoven Fabric for Medical

Our medical-grade spunlace nonwoven fabric is crafted from a blend of viscose, polyester, and other high-quality fibers, ensuring excellent softness, durability, and hygiene.

Specifically designed for medical use, this fabric offers superior absorbency, exceptional breathability, and reliable lint-free performance. This makes it an ideal choice for critical applications like wound care, surgical drapes, and a wide range of disposable medical products.

product introduce

Spunlace Nonwoven Fabric for Medical Product Highlights:

- Medical-Grade Quality: Made from a specific blend of viscose and polyester to meet strict hygiene and safety standards for medical use.

- Superior Absorbency: This fabric efficiently absorbs fluids, making it ideal for everything from wound dressings to medical wipes.

- Gentle on Skin: It’s soft and non-irritating, ensuring maximum comfort for both patients and healthcare professionals.

- Wide-Ranging Applications: Our fabric is perfect for surgical drapes, gowns, wound care products, and all sorts of disposable medical supplies.

additional information

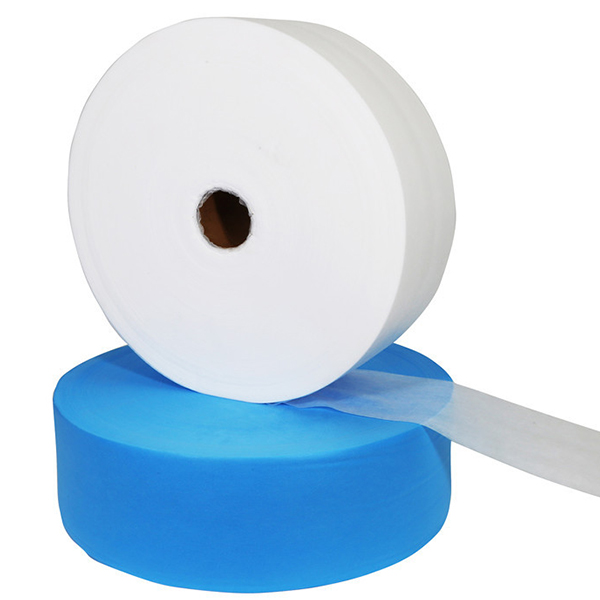

Spunlace Nonwoven Fabric for Medical Product Specifications

| Product Name | Material | Weight (g/m²) | Width (cm) | Advantages | Applications |

| Spunlace Nonwoven Fabric for Medical Dressing | Chitosan / Polyester / Viscose | 30–50 | 10–320 | Protects wounds and promotes healing. Very soft, good attaching ability, and good breathability. | Wound paste, bandages, gauze. |

| Spunlace Nonwoven Fabric for Surgical Drapes | Polyester / Viscose | 40–60 | 10–320 | Even surface, soft hand feeling, sterilized and easy to process. | Surgical beddings, surgical hole towels, medical bed sheets, production pads. |

| Spunlace Nonwoven Fabric for Medical Mask | Polyester / Viscose | 30–50 | 10–320 | Lightweight, even surface, excellent breathability, hygienic production environment without human stimulation. | Medical protection masks, surgical masks, household protection masks. |

| Spunlace Nonwoven Fabric for Medical Protective | Polyester / Viscose / Woodpulp | 50–80 | 10–320 | Highly durable and protective fabric, excellent in safeguarding medical equipment, reliable for diverse industry use. | Maintenance of medical tools, pharmaceutical, chemical industries, and food equipment. |

Related Products

Stay Ahead With UNT Updates

This article explains fusing interlining, how it works, common types, applications, and practical tips for proper fusing.

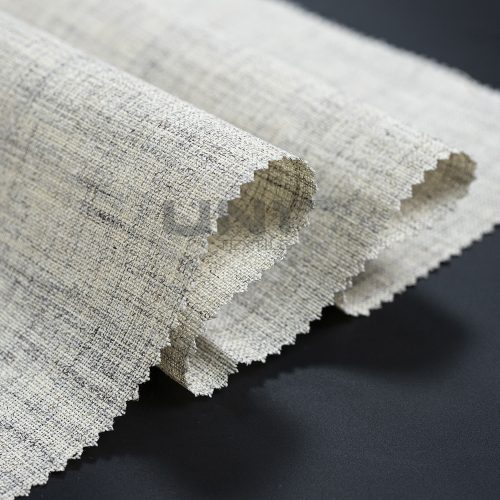

This article gives a full overview of interlining, including coating types, product categories, structures, features, and common uses.

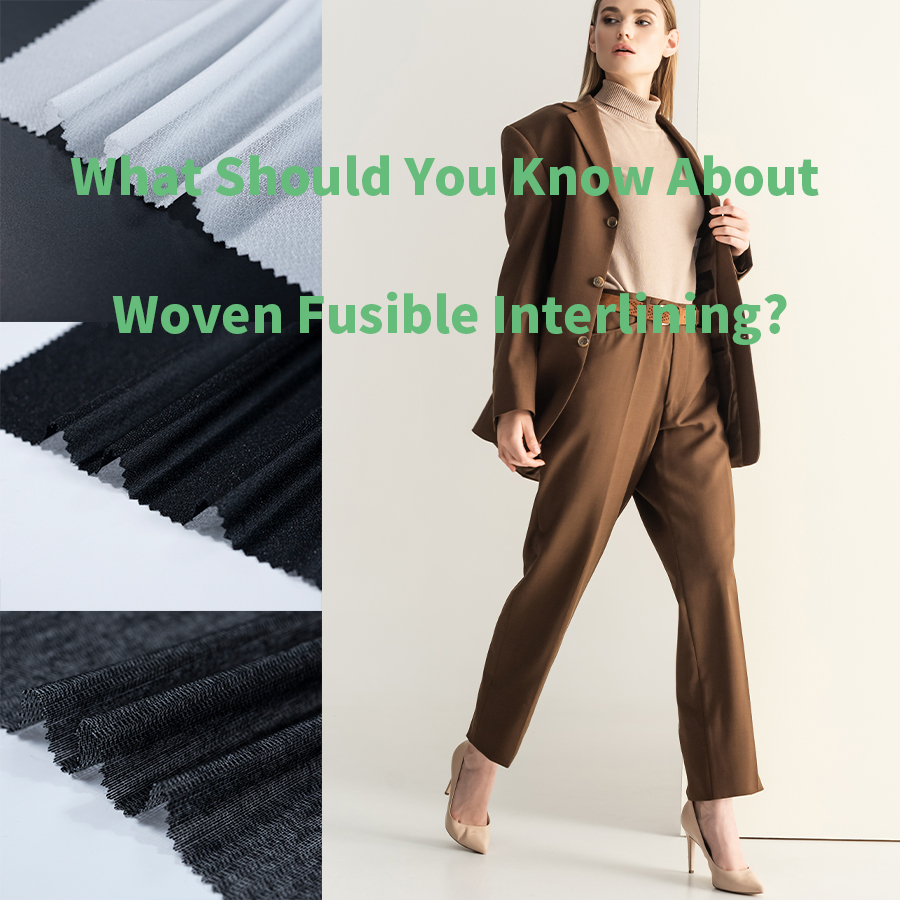

This article explains woven fusible interlining, how it works, where it’s used, and how to choose the right one.

.png)