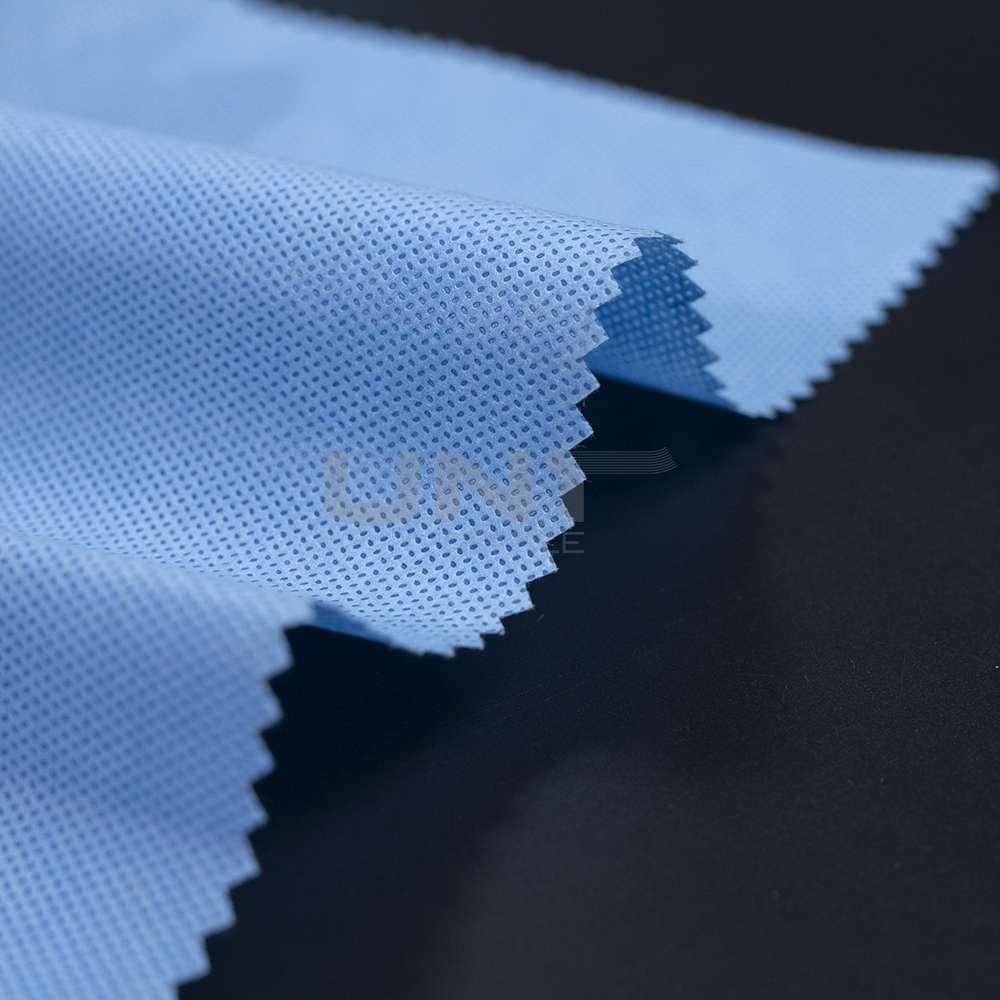

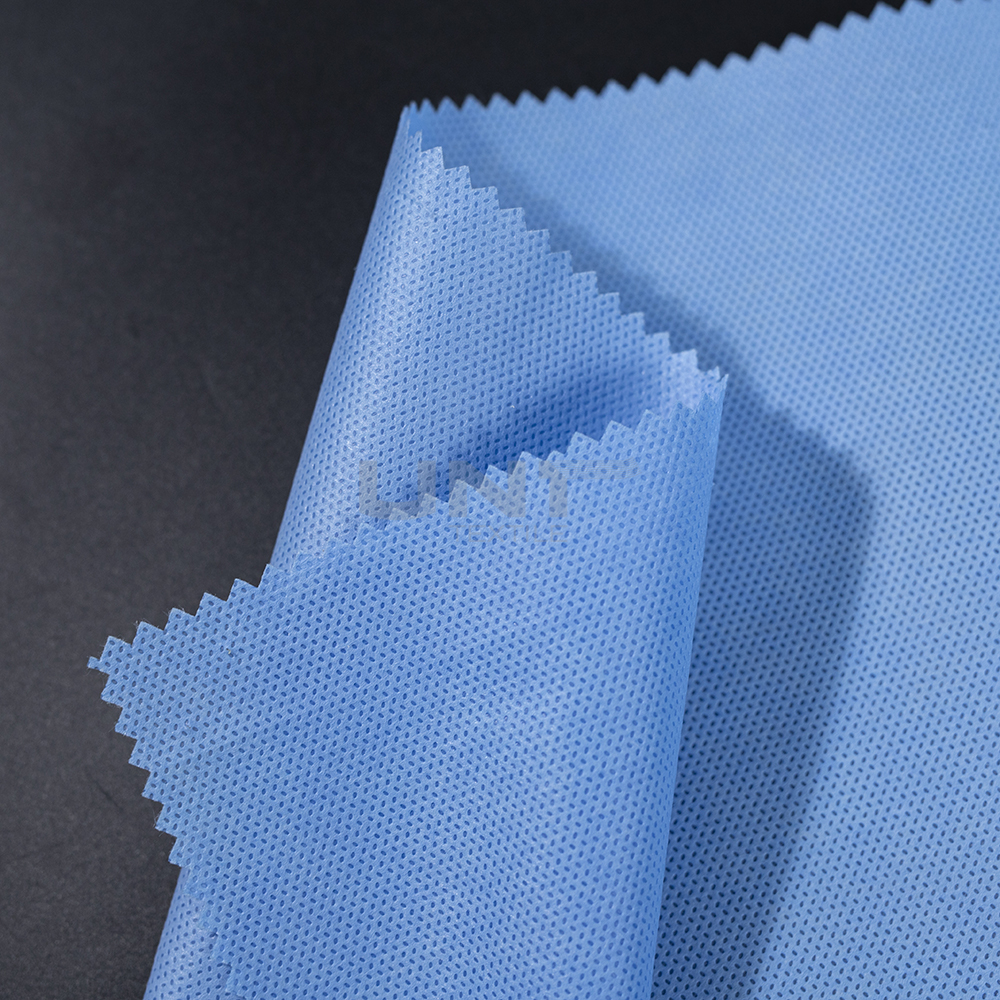

Spunmelt Nonwoven Fabric

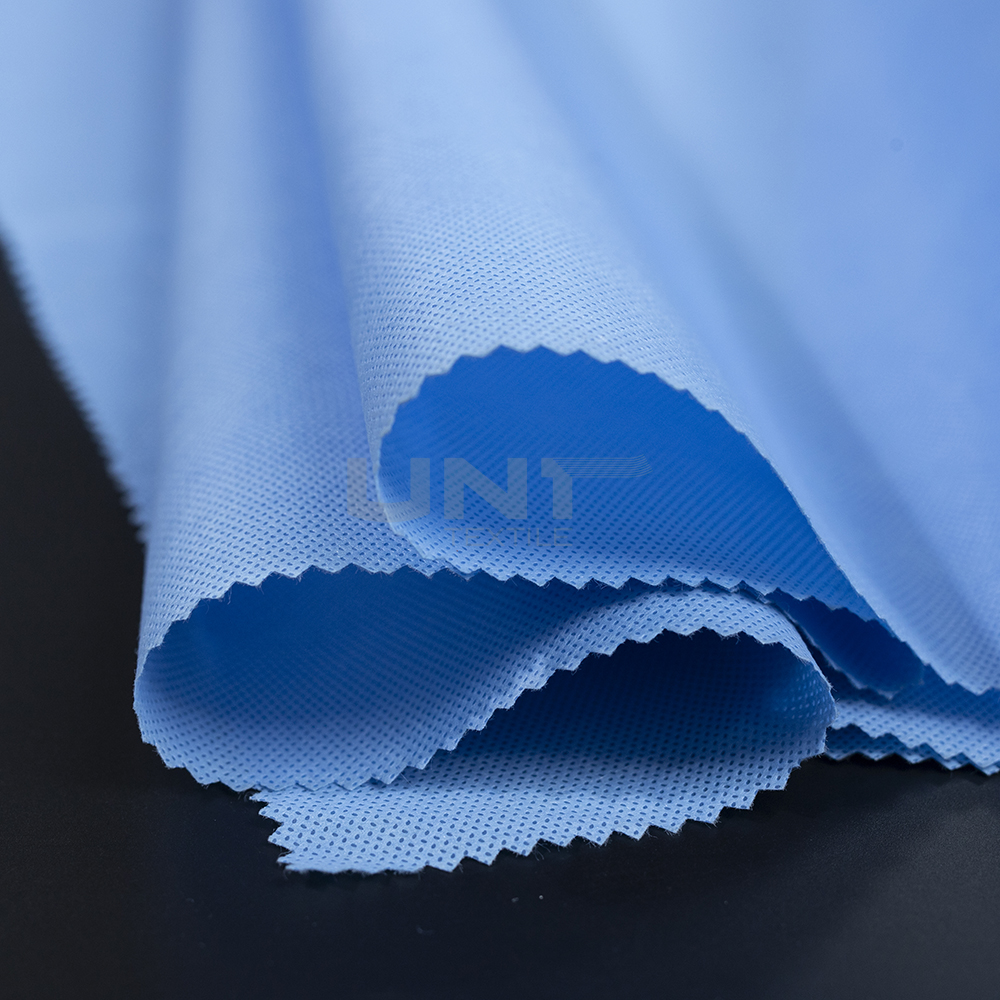

Spunmelt nonwoven fabric is a high-performance material created by ingeniously combining spunbond and meltblown layers. Our series includes versatile options like SMS, SMMS, SMMMS, and SSMMS, with a broad weight range of 10-60 gsm and widths up to 320 cm.

Available in essential colors such as white, light blue, green, and pink, our spunmelt fabric offers a host of beneficial properties. These include hydrophilic, anti-bacterial, anti-static, and our specialized “Three-Anti” (water, oil, and alcohol resistance) features.

It’s widely used across home textiles, medical, and healthcare applications, making it ideal for products like comfortable pillow covers, absorbent diapers, effective wet wipes, protective surgical and isolation gowns, and reliable medical curtains.

product introduce

Spunmelt Nonwoven Fabric Product Highlights:

- Enhanced Durability: Our spunbond-meltblown-spunbond multi-layer structure significantly boosts strength, durability, and filtration efficiency.

- Comprehensive Protection: It offers versatile performance with anti-static, hydrophilic, and our “Three-Anti” capabilities for all-around protection.

- Broad Applications: Perfect for medical, hygiene, and home textile products, our fabric consistently meets strict industry standards.

- Tailored to Your Needs: We provide customizable options including various weights, widths, and colors to perfectly cater to your diverse customer requirements.

additional information

Spunmelt Nonwoven Fabric Product Specifications

| Product Series | SMS Series, SMMS Series, SMMMS Series, SSMMS Series |

| Weight | 10-60 gsm |

| Width | 2-320 cm |

| Color | White, Light Blue, Green, Pink, etc. |

| Function | Hydrophilic, Anti-Bacterial, Anti-Static, Three-Anti, Super Soft, etc. |

| Application Area | Home Textile, Medical and Health Care |

| Application Product | Pillow Cover, Diaper, Wet Wipes, Sanitary Pad, Protection Wear, Surgical Gown, Isolation Gown, Medical Partition Curtain, etc. |

| Minimum Order Quantity | 500kg per type |

| Certification | OEKO-TEX, GRS, SGS |

| Price Range | USD $1.5 – $2.5/kg (Depending on material and weight) |

| Packaging | Roll packed in PE plastic bags, with an outer strong woven polybag |

| Transportation | Via sea, air, or express logistics |

| Payment Terms | L/C, D/P, T/T, Western Union, PayPal |

| Delivery Time | 7-15 days based on order size |

| Monthly Production Capacity | 2,000,000 meters |

| Roll Length | 100m-1000m/roll |

| Special Customization | Available for color, weight, and width upon request |

Related Products

Stay Ahead With UNT Updates

This article explains fusing interlining, how it works, common types, applications, and practical tips for proper fusing.

This article gives a full overview of interlining, including coating types, product categories, structures, features, and common uses.

This article explains woven fusible interlining, how it works, where it’s used, and how to choose the right one.

.png)