Tie Interlining

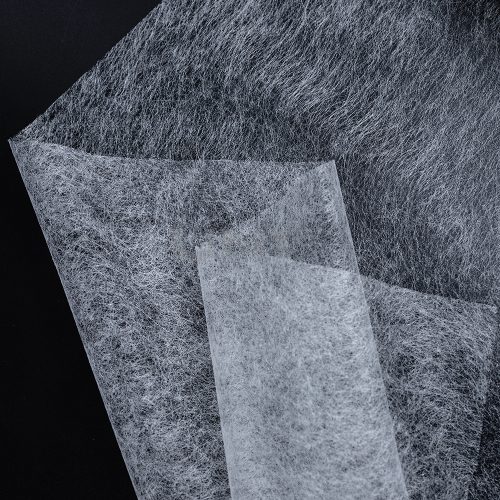

Tie interlining is a crucial material used to give neckties their shape, stability, and that luxurious feel. It ensures the tie maintains its structure while still allowing it to drape naturally. Made from high-quality fabrics like wool, polyester, or various blends, our tie interlining is a perfect fit for a wide range of tie styles, from casual to formal.

product introduce

Tie Interlining Product Highlights:

- Superior Shape Retention: Our interlining keeps ties structured and wrinkle-free, ensuring a polished, professional appearance.

- Smooth Drape and Feel: It enhances the softness and flexibility of a tie for a comfortable wearing experience.

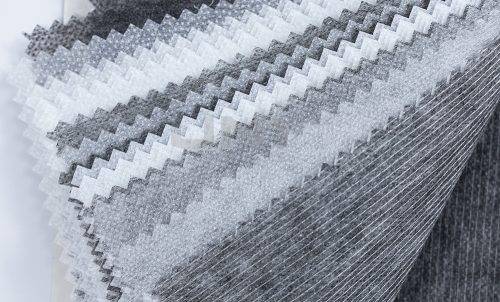

- Versatile Options: With options in wool, polyester, and blended materials, it’s easy to find the perfect fit for any tie design or fabric.

- Durable and Long-Lasting: This interlining maintains shape and quality over time, even with frequent wear and washing.

additional information

| Material | 100% Polyester, Polyester/Wool, Polyester/Viscose/Wool, 100% Wool |

|---|---|

| Width | 150cm |

| Weight | 200gsm – 450gsm |

| Roll Length | 50-60 meters per roll |

| MOQ (Minimum Order Quantity) | 500 meters |

| Certificates | OEKO-TEX, SGS |

| Price | 0.5 – 3 USD per meter |

| Packaging | PE plastic bag and Nylon bag; the roll packed by transparent strong plastic bag, the outside by strong woven polybag. |

| Transportation | By sea, air, or express |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union |

| Delivery Time | 7-15 days |

| Monthly Production | 1,000,000 meters |

| Applications | Suitable for middle and high-grade suit ties. Hand feeling can be customized. |

| Characteristics | High elasticity, durable structure, shrink-resistant, excellent bonding strength, soft and smooth texture |

Related Products

Stay Ahead With UNT Updates

This article explains fusing interlining, how it works, common types, applications, and practical tips for proper fusing.

This article gives a full overview of interlining, including coating types, product categories, structures, features, and common uses.

This article explains woven fusible interlining, how it works, where it’s used, and how to choose the right one.

.png)