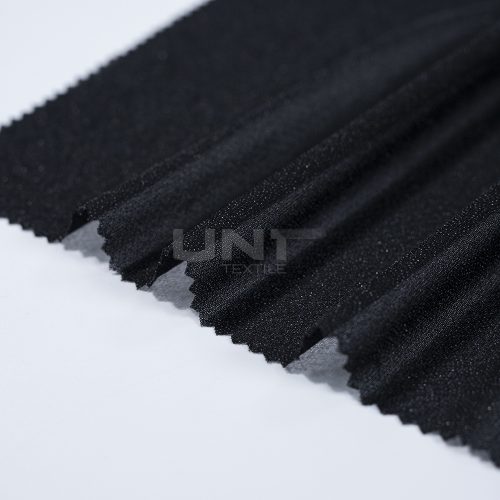

Twill Weave Interlining

Twill weave interlining is the perfect choice for both men’s and women’s wear, especially when working with heavy fabrics. Known for its excellent elasticity and durability, it’s ideal for front fuses, blouse collars, and other small, detailed parts.

As a wholesale provider, our interlining stands out with its consistent quality, a wide range of customizable options, and professional support. We’re ready to meet all of your diverse customer needs.

product introduce

Twill Woven Interlining Product Highlights:

- Superior Elasticity: It provides superior elasticity and resilience, making it perfect for garments that need flexibility and shape retention.

- Enhanced Adhesion: The distinctive twill texture boosts adhesion, ensuring a strong bond with fabrics for long-lasting performance.

- Versatile Application: Our interlining is great for both men’s and women’s apparel, from front fuses and blouse collars to small parts.

- Customizable for Your Needs: We support customization in density and finish, so you can meet the diverse needs of high-end garment production.

additional information

| Material | 100% Polyester / Polyester & Viscose |

|---|---|

| Width | 122cm, 150cm |

| Color | White, Optical White, Black, Grey |

| Weight | 30gsm – 160gsm |

| MOQ (Minimum Order Quantity) | 500 meters |

| Certificates | OEKO-TEX, SGS, GRS |

| Price | 0.3 – 2.5 USD per meter |

| Packaging | PE plastic bag and Nylon bag; the roll packed by transparent strong plastic bag, the outside by strong woven polybag. |

| Transportation | By sea, air, or express |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union |

| Delivery Time | 7-15 days |

| Monthly Production | 1,000,000 meters |

| Roll Length | 100 meters per roll |

| Adhesive Types | Double-dot Coating, Paste-dot Coating |

| Stiffness Options | Soft, medium, and hard stiffness for tailored needs |

| Thermal Properties | Fusing temperature range: 120-160°C |

| Washing Properties | Durable for both home washing and industrial dry cleaning |

| Shrink Resistance | Ensures fabric alignment with minimal shrinkage after fusing |

| Surface Finish | Fine twill texture for smooth bonding and enhanced appearance |

| Applications | Men's and women's suits, heavy-weight fabrics, front fuse, blouse collar, and small parts |

Related Products

Stay Ahead With UNT Updates

This article explains fusing interlining, how it works, common types, applications, and practical tips for proper fusing.

This article gives a full overview of interlining, including coating types, product categories, structures, features, and common uses.

This article explains woven fusible interlining, how it works, where it’s used, and how to choose the right one.

.png)