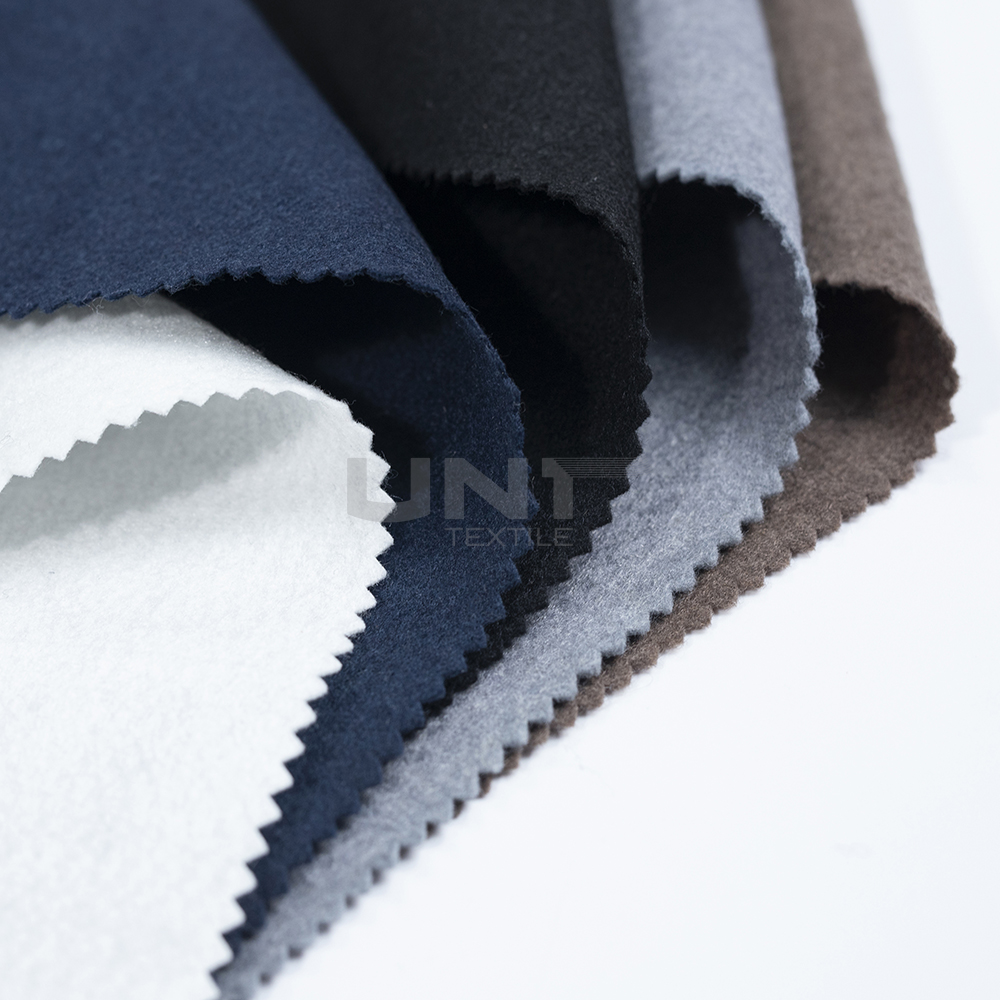

Under Collar Felt

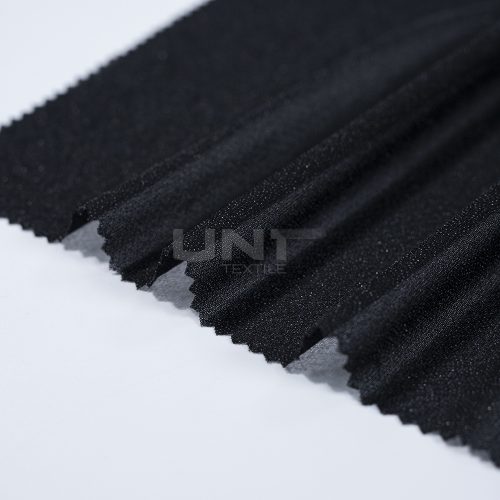

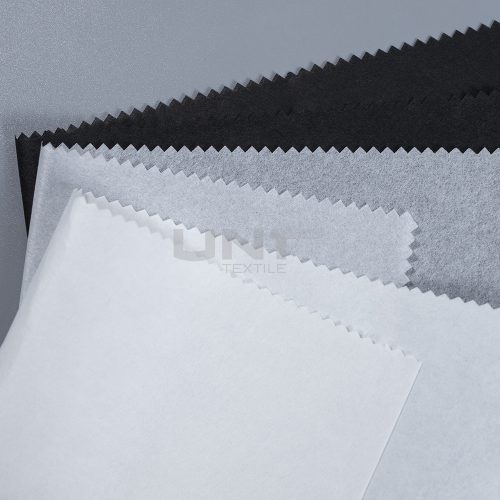

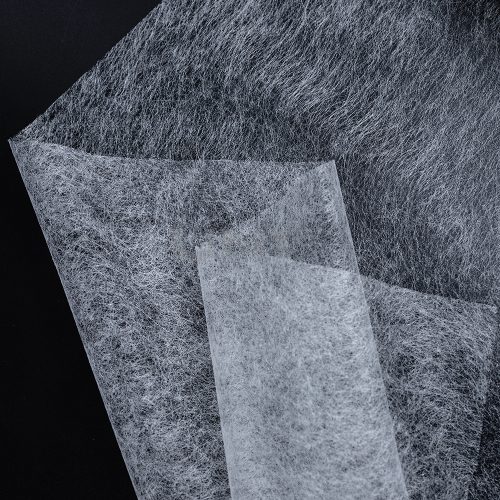

Under collar felt plays a vital role in creating high-quality coats and jackets. Made from excellent blends like 100% polyester, polyester/wool, and polyester/viscose, this material provides a smooth, supportive finish to the collar area.

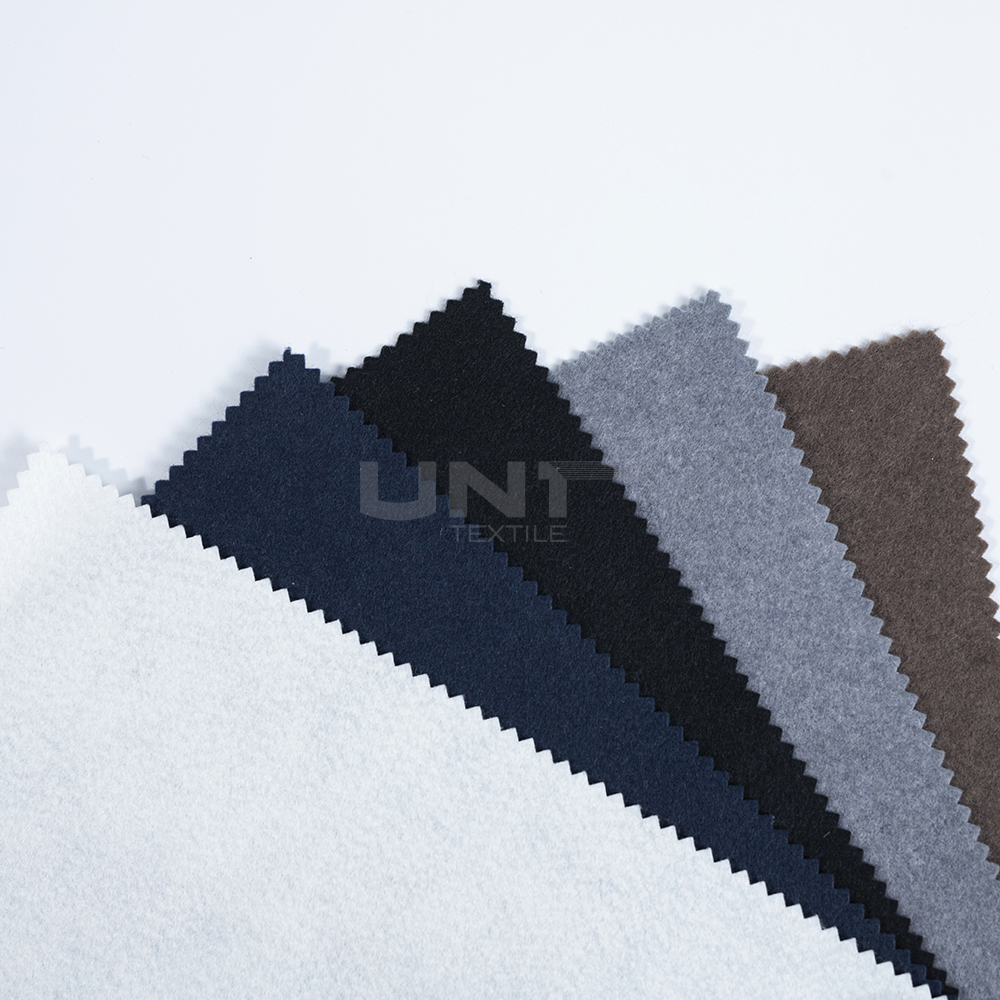

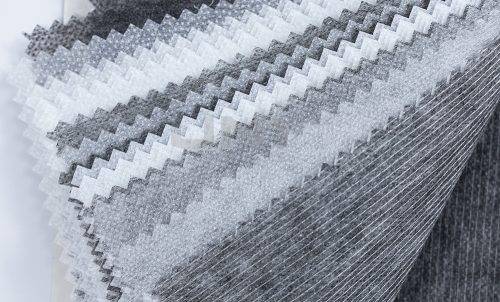

Its elasticity and wrinkle-resistant nature ensure a crisp appearance while still being easy to cut and shape. Available in various weights (160gsm–260gsm) and a wide range of customizable colors, our under collar felt is the perfect choice for precise tailoring requirements.

product introduce

Under Collar Felt Product Highlights:

- Diverse Material Blends: We offer a variety of material blends, including polyester/wool and polyester/viscose, to perfectly meet your specific tailoring needs.

- Professional Finish: This felt is both elastic and wrinkle-resistant, ensuring you get a professional, smooth finish every time in your collar construction.

- Customizable Options: We can tailor the weight, width, and color for a perfect match to your exact garment specifications.

- Durable & Easy to Handle: Our felt provides exceptional durability and is easy to handle throughout the tailoring process.

additional information

| Product Name | Under Collar Felt |

|---|---|

| Material | 100% Polyester, Polyester/Wool, Polyester/Viscose |

| Application | Mainly used for coat and jacket collar bottom, plays a supporting and shaping role |

| Width | 90cm, 150cm |

| Weight | 160gsm – 260gsm |

| Stock | Regular colors available in 165gsm |

| Color | Customizable according to customer's requirements |

| Printing | Customizable |

| Features | – Does not wrinkle or lose shape |

| Minimum Order Quantity | 500 meters |

| Price Range | USD $0.80 – $1.50/meter (Depending on material and weight) |

| Packaging | Roll packed in PE plastic bags, with outer woven polybags |

| Transportation | Via sea, air, or express logistics |

| Payment Terms | L/C, D/P, T/T, Western Union, PayPal |

| Delivery Time | 7-15 days based on order size |

| Monthly Production Capacity | 1,000,000 meters |

| Special Customization | Available for material, width, weight, and color |

| Certification | OEKO-TEX, GRS, SGS |

Related Products

Stay Ahead With UNT Updates

This article explains fusing interlining, how it works, common types, applications, and practical tips for proper fusing.

This article gives a full overview of interlining, including coating types, product categories, structures, features, and common uses.

This article explains woven fusible interlining, how it works, where it’s used, and how to choose the right one.

.png)