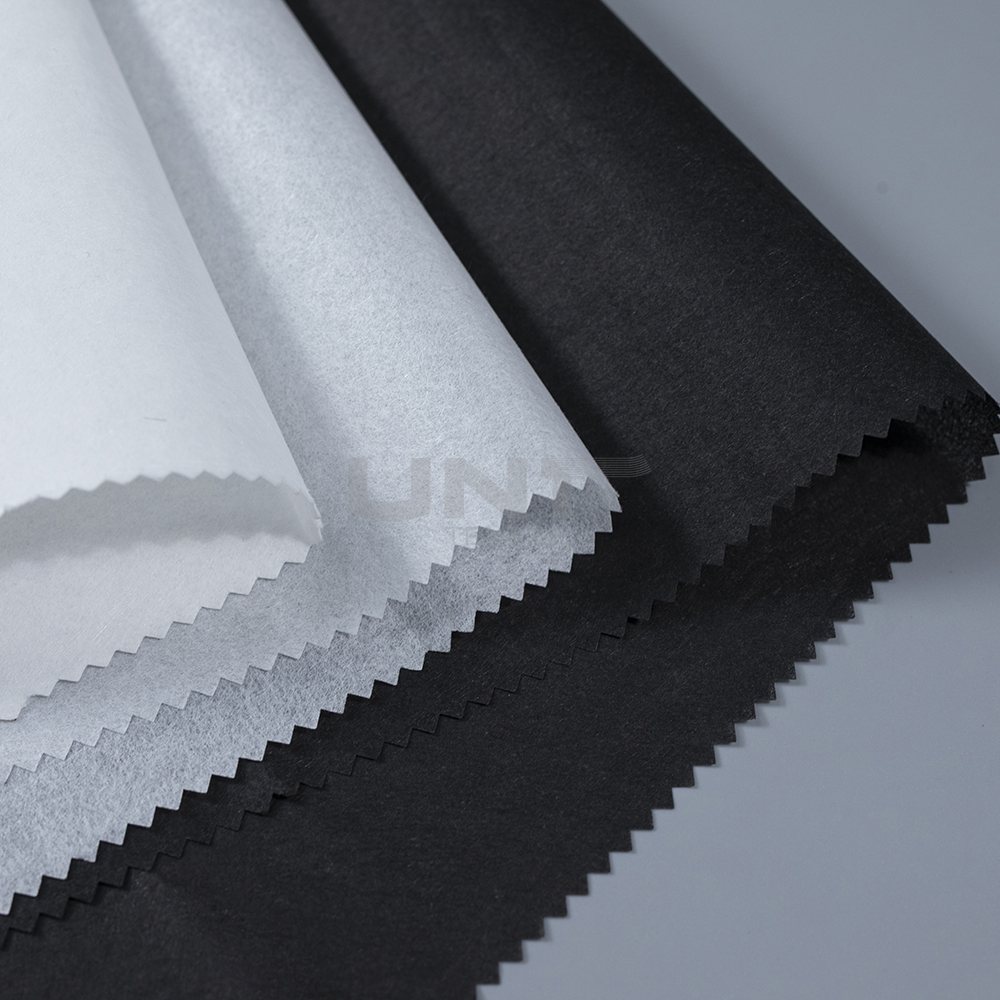

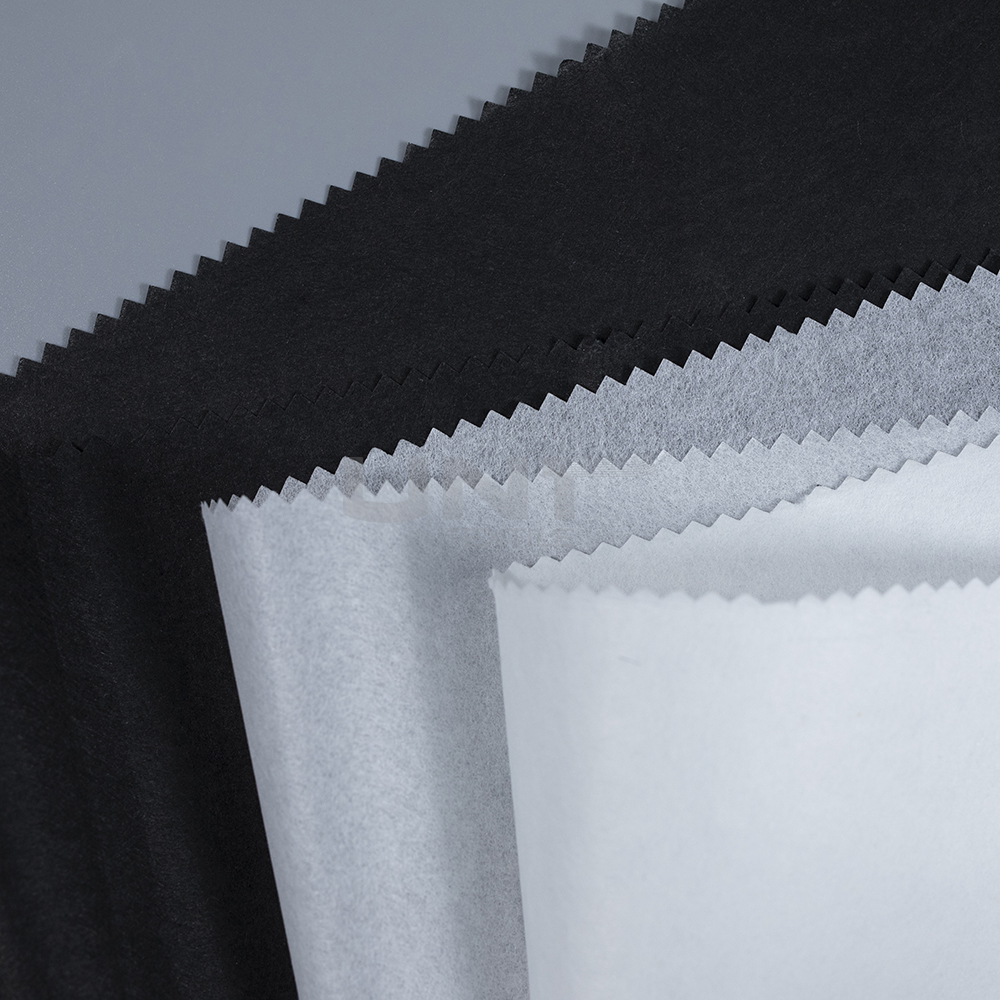

Wet Laid Embroidery Backing

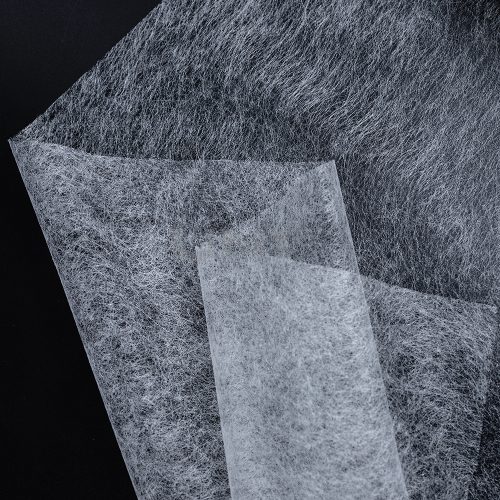

Our Wet Laid Embroidery Backing is a premium stabilizer crafted using wet-laid nonwoven technology. It’s known for its excellent uniformity, incredible softness, and reliable strength, making it an ideal choice for supporting intricate embroidery designs.

Commonly used in garments, home textiles, and industrial embroidery, it ensures you get precise and professional stitching results every time.

product introduce

Wet Laid Embroidery Backing Product Highlights:

- Uniform & Stable: Wet-laid technology provides consistent thickness and stability, ensuring your embroidery is completely free of distortion.

- Soft yet Strong: Our backing balances a gentle touch on fabrics with robust support, even for detailed and high-density embroidery patterns.

- Eco-Friendly Production: Manufactured with minimal environmental impact, it supports sustainability in all your embroidery applications.

- Wide Application Range: It’s an ideal choice for garments, home décor, industrial embroidery, and a variety of other creative projects.

additional information

| Product Name | Wet Laid Embroidery Backing |

|---|---|

| Material | Viscose Fiber + Polyester Blend |

| Weight Range | 30-80gsm |

| Width Range | 90cm-160cm |

| Color | White, Off-White |

| Pattern | Smooth, Uniform Surface |

| Application | Ideal for delicate embroidery projects, lightweight fabrics like chiffon, silk, and georgette |

| Function | High wet strength, excellent water solubility for tear-away and wash-away embroidery backing |

| Minimum Order Quantity | 5,000 meters per type |

| Price Range | USD $0.1 – $1/meter (Depending on weight and customization) |

| Packaging | Rolled on paper cores, packed in waterproof PE plastic bags with outer woven polybag |

| Transportation | Via sea, air, or express logistics |

| Payment Terms | L/C, D/P, T/T, Western Union, PayPal |

| Delivery Time | 7-15 days based on order size |

| Monthly Production Capacity | 2,500,000 meters |

| Roll Length | 50m-300m/roll (Customizable) |

| Special Customization | Available for width, weight, and material composition upon request |

| Certification | OEKO-TEX, SGS, ISO9001 |

Related Products

Stay Ahead With UNT Updates

This article explains fusing interlining, how it works, common types, applications, and practical tips for proper fusing.

This article gives a full overview of interlining, including coating types, product categories, structures, features, and common uses.

This article explains woven fusible interlining, how it works, where it’s used, and how to choose the right one.

.png)