What Do You Need to Know About Interlining?

Interlinings is a hidden but essential part of garment production. It supports shape, improves fit, and helps garments keep their form after washing and wearing. Although customers rarely see it, manufacturers know that choosing the right interlining can directly affect garment quality.

This article provides a complete overview of interlinings, from coating materials and product types to structures, features, and real-world applications.

What Is Interlining?

Is a layer placed between the outer fabric and the lining or shell of a garment. It can be fused with heat or sewn in, depending on the type.

Its main purpose is to:

-

Add structure

-

Improve shape retention

-

Support specific garment areas

-

Enhance durability

Interlining Coating Types

Most fusible interlinings use hot melt adhesive coatings. Different coatings are chosen based on fabric type, washing requirements, and end use.

PA (Polyamide)

-

Strong bonding performance

-

Good wash resistance

-

Widely used in shirts, jackets, and workwear

PES (Polyester)

-

Higher heat resistance

-

Stable performance

-

Suitable for garments requiring durability

EVA

-

Lower fusing temperature

-

Softer hand feel

-

Often used for lightweight fabrics

TPU

-

Elastic and flexible

-

Good recovery

-

Used for stretch garments and special applications

Additional Notes

Different coatings react differently to heat and pressure. Choosing the right coating helps prevent bonding failure, fabric damage, or surface marks.

Testing with the actual outer fabric is always recommended.

Main Types of Interlining

Can be divided into several major categories based on structure and application.

Woven Interlining

Woven interlinings is made with traditional weaving methods. It offers clear structure and good stability.

Plain

-

Simple structure

-

Very stable

-

Used in shirts, plackets, basic garments

Twill

-

Diagonal weave

-

Softer feel than plain

-

Common in jackets and coats

Warp Knit

-

Stable with slight flexibility

-

Used in fashion garments and casual wear

Weft Insert Napping

-

Soft surface with support

-

Suitable for garments needing comfort and shape

Circular Knit

-

More elastic

-

Used with stretch or knitted fabrics

Tricot

-

Smooth surface with light sheen

-

Used in high-quality shirts and blouses

Additional Notes

When choosing woven interlining, fabric direction is important. Matching the grain direction of the interlining with the outer fabric helps improve garment stability and appearance after washing.

Is often preferred for garments that require sharp edges and long-term shape retention.

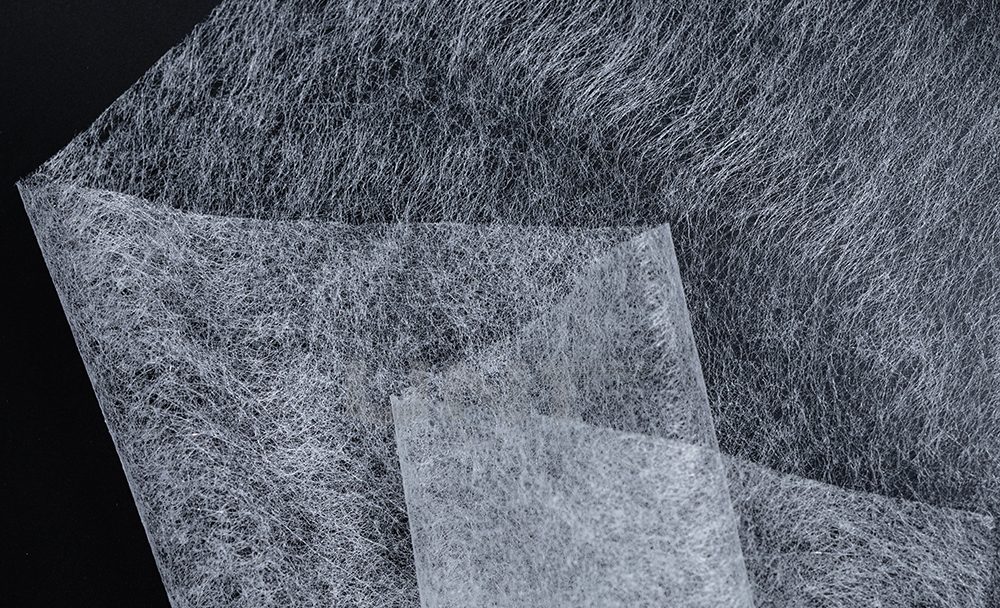

Nonwoven Interlining

Nonwoven interlinings is made without weaving or knitting. It’s easy to handle and widely used in mass production.

Chemical Bond Nonwoven

-

Fibers bonded with chemical agents

-

Stable and cost-effective

-

Used in shirts and casual wear

Thermal Bond Nonwoven

-

Heat-bonded fibers

-

Clean structure and even thickness

-

Suitable for consistent quality needs

Elastic Nonwoven

-

Controlled stretch

-

Used in areas requiring flexibility

Spunlace Nonwoven

-

Soft and breathable

-

Better drape

-

Used where comfort matters

Additional Notes

Is easier to cut and handle, especially in mass production. It’s a practical choice when efficiency and consistency are important.

For lightweight garments, softer nonwoven options help avoid stiffness and improve comfort.

Shirt Interlining (Collar Interlining)

Shirt interlinings is mainly used for:

-

Collars

-

Cuffs

-

Plackets

It helps shirts keep a neat shape and clean edges while remaining comfortable to wear.

Additional Notes

Collar interlining directly affects how a shirt looks when worn. A collar that is too soft may collapse, while one that is too hard may feel uncomfortable.

Testing different stiffness levels helps find the right balance for each shirt style.

Hair Interlining

Hair interlinings is traditionally used in tailored garments.

-

Made from blends of hair fibers and other yarns

-

Sew-in type

-

Used in suits, coats, and formal wear

It provides natural structure and long-lasting shape.

Additional Notes

Is usually chosen for high-end tailoring. It allows garments to age naturally and adapt to the wearer over time.

This type is still valued in classic suits and coats where craftsmanship matters.

Tie Interlining

Tie interlinings controls the shape and drape of neckties.

-

Affects thickness and flexibility

-

Helps ties recover after use

Different stiffness levels are chosen based on design style.

Additional Notes

Tie interlining controls not only shape but also knot size. Thicker interlining creates fuller knots, while thinner options result in a cleaner look.

Design preference plays a key role in selection.

Waistband Interlining

Waistband interlining supports garment waist areas.

-

Helps maintain shape

-

Improves comfort and durability

-

Often elastic or reinforced

Commonly used in trousers, skirts, and uniforms.

Additional Notes

Waistband interlining must balance support and comfort. Too stiff and it feels tight; too soft and it loses shape.

Elastic waistband interlining is often used in garments designed for movement and long wear.

Hot Melt Adhesive Web

It does not provide structure by itself but works as a bonding layer.

PA Hot Melt Web

-

Strong bonding

-

Widely used

EVA Hot Melt Web

-

Low melting point

-

Soft bonding

PES Hot Melt Web

-

Heat resistant

-

Stable

TPU Hot Melt Web

-

Elastic bonding

-

Used for stretch applications

Hot melt adhesive web is commonly used for laminating fabrics and bonding layers evenly.

Additional Notes on Hot Melt Adhesive Web

Hot melt adhesive web is especially useful when uniform bonding is required across large areas.

It’s widely used in fabric lamination, composite materials, and technical garments where sewing is not ideal.

How to Choose the Right Interlining

-

Match interlining weight with outer fabric

-

Check shrinkage compatibility

-

Choose correct adhesive type

-

Always test before bulk production

Good interlining selection reduces defects and improves final garment quality.

More Practical Tips for Choosing Interlining

In real production, choosing interlining is not only about structure. It’s also about how the garment will be worn, washed, and produced.

Consider the Final Garment Style

Formal garments usually need firmer interlining, while casual garments require more comfort and flexibility.

Think About Washing and Care

Garments that are frequently washed need interlining with stable bonding and low shrinkage.

Check Production Conditions

Different factories use different fusing machines. Interlining should match available temperature and pressure ranges.

Balance Cost and Performance

The most expensive option is not always necessary. The right match often performs better than an over-specified product.

FAQ

Q1: Is fusible interlining better than sew-in?

Fusible is easier and faster, but sew-in types are still used in tailored garments.

Q2: Can one interlining be used for all garments?

No, different garments require different structures and performance.

Q3: Does interlining affect comfort?

Yes, especially in areas like collars, waistbands, and cuffs.

Q4: Should interlining be tested before production?

Yes, testing helps avoid bonding and shrinkage issues.

Why Choose Shanghai Uneed Textile Co., Ltd.?

-

Full Interlining Product Range

Woven, nonwoven, specialty, and adhesive solutions. -

Professional Product Knowledge

Real experience in garment applications. -

Strict Quality Control

Shrinkage, bonding strength, and stability testing. -

Flexible Custom Options

Weight, coating, and structure adjustments. -

Reliable Export Experience

Stable supply and clear communication.

continue reading

Related Posts

This article explains fusing interlining, how it works, common types, applications, and practical tips for proper fusing.

This article gives a full overview of interlining, including coating types, product categories, structures, features, and common uses.

This article explains nonwoven fusible interlining, its features, uses, and how to choose the right type for garments.

.png)