What Do You Need to Know About Nonwoven Fusible Interlining?

Nonwoven fusible interlining is one of the most commonly used interlinings in garment production. It’s popular because it’s easy to use, stable in quality, and suitable for many different types of clothing. Although it’s not visible in finished garments, it plays an important role in shape, comfort, and durability.

In this article, we’ll explain what nonwoven fusible interlining is, how it’s used, and what to look for when choosing it.

What Is Nonwoven Fusible Interlining?

Nonwoven fusible interlining is made from fibers bonded together without weaving or knitting. One side is coated with adhesive, which allows it to bond to the outer fabric using heat and pressure.

Because it doesn’t have a warp or weft direction like woven fabric, it behaves more evenly in all directions. This makes it easy to handle during cutting and production.

Why Is Nonwoven Fusible Interlining Widely Used?

Easy to Cut and Use

There’s no grain direction to worry about, which reduces mistakes and saves time.

Stable Performance

It keeps its shape well and works consistently in mass production.

Cost-Effective

Compared with woven interlining, nonwoven options are usually more economical.

Wide Application Range

Suitable for many garment types, from shirts to casual wear.

Common Materials Used in Nonwoven Fusible Interlining

Polyester

Strong, durable, and resistant to shrinkage. Commonly used in everyday garments.

Viscose

Softer hand feel and better breathability. Often chosen for lightweight clothing.

Blended Fibers

Balance between softness and stability, suitable for a wide range of fabrics.

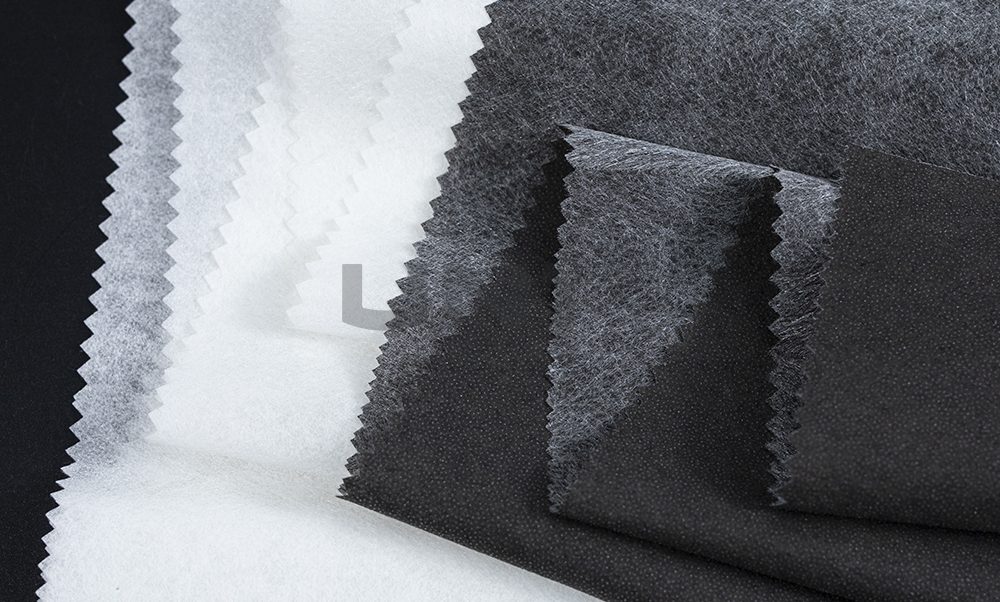

Different Types of Nonwoven Fusible Interlining

Nonwoven fusible interlining includes several different structures. Each type is designed for specific garment needs and production conditions.

Chemical Bond Nonwoven Interlining

This type is made by bonding fibers together using chemical binders. It offers good stability and is commonly used in shirts, casual wear, and basic garments. Chemical bond interlining is easy to fuse and suitable for high-volume production.

Thermal Bond Nonwoven Interlining

Thermal bond nonwoven interlining uses heat to bond fibers together. It has a cleaner structure and more consistent thickness. This type is often chosen when stable quality and smooth appearance are required.

Spunlace Nonwoven Interlining

Spunlace nonwoven interlining is produced using high-pressure water jets. It has a softer hand feel and better drape compared with other nonwoven types. It’s suitable for garments where comfort and softness are important.

Elastic Nonwoven Interlining

Elastic nonwoven interlining provides controlled stretch and recovery. It’s mainly used in garments that need flexibility, such as waist areas or parts that move frequently.

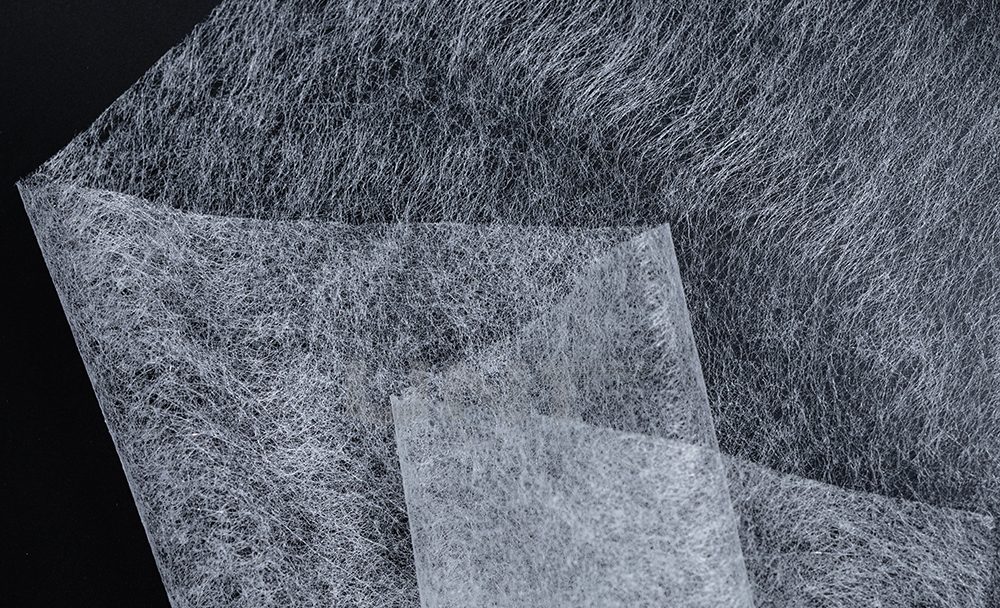

Is Hot Melt Adhesive Web a Type of Nonwoven Interlining?

Strictly speaking, hot melt adhesive web can also be considered a type of nonwoven interlining. Instead of providing fabric support by itself, it works mainly as a bonding layer. It’s widely used to laminate fabrics or bond interlining to outer materials, especially when uniform adhesion is required.

Where Is Nonwoven Fusible Interlining Used?

Shirts

Used in collars, cuffs, plackets, and front panels.

Casual Wear

Helps garments keep shape without feeling stiff.

Light Jackets

Adds support to specific areas without extra weight.

Fashion Garments

Works well when a clean shape is needed but flexibility is still important.

Nonwoven vs Woven Fusible Interlining

Nonwoven Interlining

-

Easier to handle

-

Lower cost

-

Even behavior in all directions

Woven Interlining

-

Stronger structure

-

Clear fabric direction

-

Often used for formal garments

Each type has its own place, depending on garment design and fabric choice.

How to Choose the Right Nonwoven Fusible Interlining

Match the Fabric Weight

Light fabrics need light interlining; heavy fabrics need stronger support.

Check Adhesive Quality

Good adhesive ensures stable bonding and wash durability.

Consider Shrinkage

Interlining and outer fabric should behave similarly after washing.

Test Before Bulk Production

Testing helps avoid bubbling, peeling, or hard hand feel.

Common Problems and How to Avoid Them

-

Bubbling: wrong fusing temperature or pressure

-

Hard Feel: interlining too thick for the fabric

-

Poor Bonding: low-quality adhesive or short bonding time

Most issues can be solved with proper testing and selection.

FAQ

Q1: Is nonwoven fusible interlining washable?

Yes, when properly fused, it performs well in regular washing.

Q2: Can it be used on stretch fabrics?

It can, but knitted interlining may be a better choice for high stretch fabrics.

Q3: Does nonwoven interlining shrink?

High-quality products have controlled shrinkage.

Q4: Is it suitable for mass production?

Yes, it’s widely used in large-scale garment manufacturing.

Why Choose Shanghai Uneed Textile Co., Ltd.?

-

Specialized in Interlining Products

Strong experience with woven, knitted, and nonwoven interlining. -

Consistent Quality Control

Tested for bonding strength, shrinkage, and stability. -

Wide Product Range

Different weights, materials, and adhesive options available. -

Reliable Export Service

Clear communication and stable supply for overseas customers. -

Practical Technical Support

Recommendations based on real garment production needs.

continue reading

Related Posts

This article explains fusing interlining, how it works, common types, applications, and practical tips for proper fusing.

This article gives a full overview of interlining, including coating types, product categories, structures, features, and common uses.

This article explains nonwoven fusible interlining, its features, uses, and how to choose the right type for garments.

.png)