What Should You Know About Nonwoven Interlining?

What Should You Know About Nonwoven Interlining?

Introduction

In the garment industry, interlining plays a vital role in giving structure, stability, and shape to clothing. Among its many types, nonwoven interlining is one of the most versatile and widely used. It’s found in shirts, suits, coats, and many other garments. Understanding what nonwoven interlining is, how it differs from woven interlining, and its advantages and disadvantages can help both manufacturers and consumers make better fabric choices.

What Is Nonwoven Interlining?

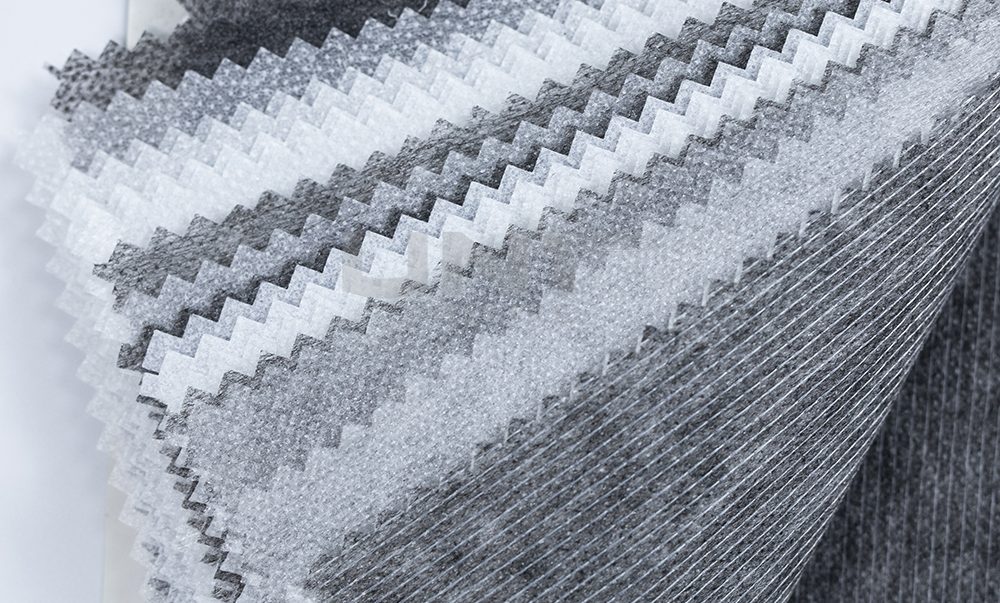

Nonwoven interlining is a type of fabric made by bonding fibers together mechanically, chemically, or thermally, rather than weaving or knitting them. It’s usually used between the outer fabric and the lining to provide shape and reinforcement without adding too much thickness.

This material is often fusible, meaning it has a layer of adhesive on one side that bonds to fabric when heat and pressure are applied. However, non-fusible types are also available for specific garment requirements.

How Does Nonwoven Interlining Differ from Woven Interlining?

Before learning about nonwoven interlining, it’s helpful to understand woven interlining first.

Woven interlining feels like regular fabric, made by interlacing threads in a specific direction. Because of this structure, it must be cut along the grain to maintain stability and avoid distortion during fusing.

In contrast, nonwoven interlining looks and feels more like a sheet of paper rather than fabric. One of its biggest advantages is flexibility — you can cut it in any direction without worrying about grainline alignment. The fibers are compressed together, and one side is coated with a layer of fusible adhesive, which makes it easy to apply and highly adaptable in garment production.

How Is Nonwoven Interlining Manufactured?

-

Fiber Selection & Blending

Manufacturers choose fibers such as polyester, nylon, or blends, often mixing for strength, flexibility, and compatibility with adhesives. -

Web Formation

Fibers are laid into a web structure by processes like airlaying, carding, or cross-lapping. -

Bonding Methods

The web is consolidated using thermal bonding, chemical adhesives, or mechanical entangling (e.g. needle punching). Strong nonwovens typically use optimized bonding to ensure dimensional stability and durability. -

Adhesive Application (for Fusible Types)

For fusible nonwoven interlinings, a thermoplastic adhesive is applied (as powder, dot, or film) onto one side. Careful control of adhesive amount and particle size is crucial to avoid defects. -

Finishing & Inspection

Calendering, smoothing, and inspections for uniformity, weight, and defects complete the process.

Thermal Bond Nonwoven Interlining

What Are the Advantages of Nonwoven Interlining?

Nonwoven interlining is popular because it offers several practical benefits:

-

Easy to Use – It can be cut in any direction, simplifying production and reducing material waste.

-

Lightweight and Thin – It adds body and structure without increasing garment bulk.

-

Cost-Effective – Generally less expensive than woven interlining, ideal for large-scale production.

-

Stable and Uniform – Has no yarn direction, so it’s less likely to distort after fusing.

-

Versatile Applications – Suitable for shirts, dresses, uniforms, and many other garments.

What Are the Disadvantages of Nonwoven Interlining?

While nonwoven interlining is convenient, it also has some limitations:

-

Lower Durability – It may not be as strong or long-lasting as woven types under repeated stress.

-

Limited Breathability – The dense fiber structure can restrict air flow in some fabrics.

-

Less Natural Drape – It may slightly stiffen light fabrics if not carefully selected.

-

Adhesive Sensitivity – Poor fusing temperature or pressure can cause bubbling or weak adhesion.

These drawbacks are manageable with proper material selection and correct fusing techniques.

Applications of Nonwoven Interlining

Nonwoven interlining is used in a wide variety of garments and accessories:

-

Shirts and Blouses: In collars, cuffs, and plackets for shape retention.

-

Jackets and Coats: Adds stability to front panels, facings, and lapels.

-

Uniforms and Workwear: Reinforces fabric for durability and clean appearance.

-

Home Textiles: In curtains, cushion covers, and craft items requiring structure.

How to Choose the Right Nonwoven Interlining?

-

Match Weight & GSM

Select weight appropriate for your fabric (e.g. light, medium, heavy) to avoid mismatch. -

Adhesive Type & Paste Point

Ensure adhesive paste point suits your fusing line (heat, time). -

Shrinkage Compatibility

Choose interlining whose dimensional changes under heat closely match your outer fabric to avoid puckers. -

Hand Feel & Flexibility

Test sample pieces to make sure it doesn’t overly stiffen. -

Test Under Real Conditions

Run wash, pressing, and wear trials before committing to mass production.

How Do Manufacturers Ensure Quality of Strong Nonwoven Interlining?

-

Raw Material Traceability

Every fiber batch is tested and documented to ensure consistency. -

Process Control (Temperature, Pressure, Time)

Advanced machines precisely regulate fusing conditions to avoid adhesives under- or over-activation. -

Peel & Adhesion Testing

Regular peel strength tests and wash cycle tests verify bond integrity. -

Visual & Microscopic Inspection

Check for bubbles, adhesive clumps, uneven coating, or fiber separation. -

Accelerated Aging & Durability Tests

Simulated wear or heat cycles identify potential failures before shipment.

What Can Consumers or Garment Makers Do to Verify Quality?

-

Inspect Bonded Areas

Look at collars, cuffs, waistbands—they should be flat, clean, no bubbles or uneven adhesion. -

Touch Test & Flexing

Fold or bend the garment to see whether the interlining shifts or peels. -

First Wash/Press Trial

The interlining should hold up after the first washing or steaming without bubbling or delamination. -

Ask Supplier About Specs

Request adhesion, peel strength, paste point, and shrinkage data. Quality suppliers will provide detailed data. -

Small Sample Testing

Before large runs, test small panel fusion to validate performance in your environment.

FAQ (Frequently Asked Questions)

Q1: Is nonwoven interlining fusible?

Yes. Most nonwoven interlinings are fusible, meaning they have an adhesive coating that bonds under heat and pressure. Non-fusible options are also available.

Q2: Can I use nonwoven interlining for lightweight fabrics?

Yes, but choose a thin and soft type to maintain a natural drape and avoid stiffness.

Q3: How should I store nonwoven interlining?

Keep it in a dry, cool environment away from direct sunlight or moisture to preserve adhesive performance.

Q4: What causes bubbles after fusing?

Improper heat, pressure, or moisture can lead to bubbling. Always test before mass production.

Why Choose Shanghai Uneed Textile Co., Ltd.

At Shanghai Uneed Textile Co., Ltd., we specialize in manufacturing and exporting high-quality interlining and nonwoven fabrics.

Our advantages include:

-

Professional Production & Export Experience: Years of industry expertise and stable supply capacity.

-

High-Quality Materials: Consistent fiber composition and even adhesive coating.

-

Strict Quality Control: Every batch undergoes fusing and adhesion testing.

-

Technical Support: Expert guidance to help customers select the right type for their garments.

-

Reliable Global Service: We provide fast delivery and strong after-sales support worldwide.

continue reading

Related Posts

This article explains fusing interlining, how it works, common types, applications, and practical tips for proper fusing.

This article gives a full overview of interlining, including coating types, product categories, structures, features, and common uses.

This article explains nonwoven fusible interlining, its features, uses, and how to choose the right type for garments.

.png)