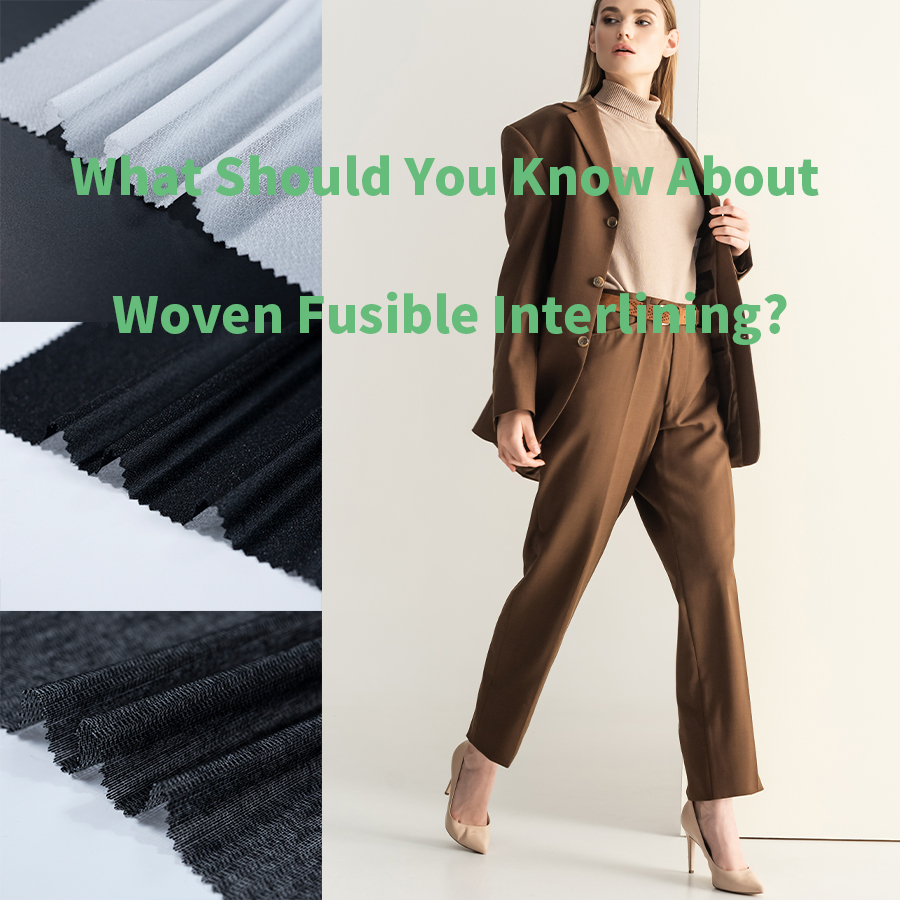

What Should You Know About Woven Fusible Interlining?

Woven fusible interlining is widely used in garments that need clear shape and long-lasting structure. You may not see it from the outside, but it plays a big role in how a garment looks, fits, and performs after washing. In this article, we’ll explain woven fusible interlining in a simple and practical way, focusing on how it’s actually used in garment production.

What Is Woven Fusible Interlining?

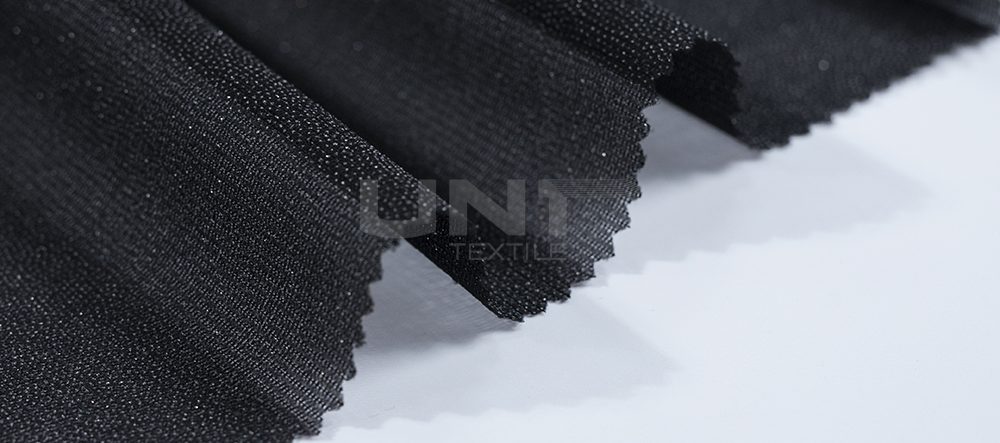

Woven fusible interlining is made from woven fabric with a layer of adhesive applied on one side.

The woven structure gives it stability, while the adhesive allows it to bond to the outer fabric using heat and pressure.

Because of this combination, woven fusible interlining is often used when garments need firm support and a clean shape.

Why Choose a Woven Structure?

Better Shape Control

Woven interlining holds its form well and helps garments keep a crisp appearance.

Good Dimensional Stability

It doesn’t stretch easily, which is important for areas that need to stay straight and flat.

Clear Fabric Direction

The warp and weft structure helps control movement and tension in specific directions.

How Does Fusible Interlining Work in Production?

The fusing process is simple but important:

-

Place the adhesive side against the outer fabric

-

Apply heat and pressure using a fusing machine

-

The adhesive melts and bonds the layers together

-

Cooling fixes the bond

Correct temperature and pressure are key to avoiding bubbling or poor bonding.

Common Materials Used in Woven Fusible Interlining

Woven fusible interlining can be made from different yarns, depending on the required performance.

Cotton

-

Natural feel

-

Good breathability

-

Often used in shirts and lightweight garments

Polyester

-

Strong and stable

-

Low shrinkage

-

Easy care and durable

Blended Fabrics

-

Balance between comfort and stability

-

Widely used in everyday garments

What Types of Woven Fusible Interlining Are Available?

Woven fusible interlining is not a single product. In real garment production, it comes in several structures, each designed for different fabric types and garment styles.

Plain Woven Interlining

Plain woven interlining has a simple over-under yarn structure. Because of this, it is very stable and easy to handle during cutting and fusing. It doesn’t stretch much in any direction, which helps keep collars, plackets, and front panels straight and neat.

This type is widely used in shirts, uniforms, and basic garments. It is also a good choice for beginners in production because it’s predictable and easy to control.

Twill Woven Interlining

Twill woven interlining uses a diagonal weave. Compared with plain weave, it feels slightly softer and follows the outer fabric more naturally. The diagonal structure also helps reduce stiffness and makes the garment look smoother after fusing.

It’s often used in jackets, coats, trousers, and garments made with twill or heavier fabrics. When a garment needs shape but not a hard feel, twill interlining is a common choice.

Warp Knit Interlining

Warp knit interlining is produced using warp knitting technology, which gives it better stability than ordinary knitted interlining. It has controlled stretch but does not deform easily after washing.

This type is suitable for fashion garments that need a balance between structure and comfort. It’s often used in women’s wear, casual jackets, and garments with softer outer fabrics.

Weft Insert Napping Interlining

Weft insert napping interlining combines inserted yarns with a soft surface finish. The napping process improves hand feel and helps the interlining blend smoothly with the outer fabric.

It provides support without making the garment feel too stiff. This type is often chosen for mid-weight garments where comfort is just as important as shape.

Circular Knit Interlining

Circular knit interlining has higher elasticity compared to woven types. It moves more freely with the outer fabric, which helps prevent cracking or pulling during wear.

It’s mainly used for garments made from stretch fabrics or knitted fabrics, especially when comfort and flexibility are key requirements.

Tricot Interlining

Tricot interlining is known for its smooth surface and slight sheen. It offers good stability while keeping a clean and refined appearance.

This type is commonly used in high-quality shirts, blouses, and garments where surface smoothness and visual quality matter. It also helps reduce fabric marks on the garment surface after fusing.

Where Is Woven Fusible Interlining Used?

Woven fusible interlining is commonly used in areas that need structure.

Shirt Collars and Cuffs

Provides firmness and keeps clean edges.

Plackets and Front Panels

Helps garments look neat and well-shaped.

Jackets and Coats

Used in lapels and front parts to maintain shape.

Formal and Workwear

Chosen for garments that require a professional appearance.

Woven Fusible Interlining vs Other Interlinings

Compared with Nonwoven Interlining

Woven interlining offers better stability and a more traditional feel.

Compared with Knitted Interlining

Woven interlining is firmer, while knitted interlining focuses more on comfort and stretch.

Each type serves a different purpose in garment design.

How to Choose the Right Woven Fusible Interlining

Match Fabric Weight

Light fabrics need light interlining; heavy fabrics need stronger support.

Check Shrinkage

Interlining and outer fabric should shrink at similar rates.

Select Proper Adhesive

Adhesive quality affects bonding strength and wash durability.

Test Before Production

Testing helps avoid problems during mass production.

Common Problems and How to Avoid Them

-

Bubbling: caused by wrong temperature or poor adhesive

-

Hard Hand Feel: interlining too heavy for the fabric

-

Peeling: insufficient pressure or bonding time

Most issues can be solved by proper selection and testing.

FAQ

Q1: Is woven fusible interlining suitable for all garments?

It’s best for garments that need structure rather than stretch.

Q2: Can it be used on lightweight fabrics?

Yes, as long as the interlining weight matches the fabric.

Q3: Does woven fusible interlining shrink after washing?

High-quality products have controlled shrinkage.

Q4: Is it washable?

Yes, when properly fused.

Why Choose Shanghai Uneed Textile Co., Ltd.?

-

Strong Interlining Expertise

Experience with woven, knitted, and nonwoven interlining. -

Strict Quality Control

Testing for shrinkage, bonding strength, and fabric stability. -

Wide Product Selection

Different weights, constructions, and adhesive types. -

Reliable Export Service

Stable supply, clear communication, and consistent quality. -

Practical Technical Support

Advice based on real garment production needs.

continue reading

Related Posts

This article explains fusing interlining, how it works, common types, applications, and practical tips for proper fusing.

This article gives a full overview of interlining, including coating types, product categories, structures, features, and common uses.

This article explains nonwoven fusible interlining, its features, uses, and how to choose the right type for garments.

.png)