How to Set the Right Fusible Interlining Bonding Conditions?

How to Set the Right Fusible Interlining Bonding Conditions?

When working with fusible interlining, setting the correct fusible interlining bonding conditions—temperature, pressure, and time—is critical to achieving durable adhesion without damaging the fabric. In this article, we’ll walk you through the factors that affect these parameters, how to test and refine your settings, and what pitfalls to avoid.

What Are the in Fusible Interlining Bonding Conditions ?

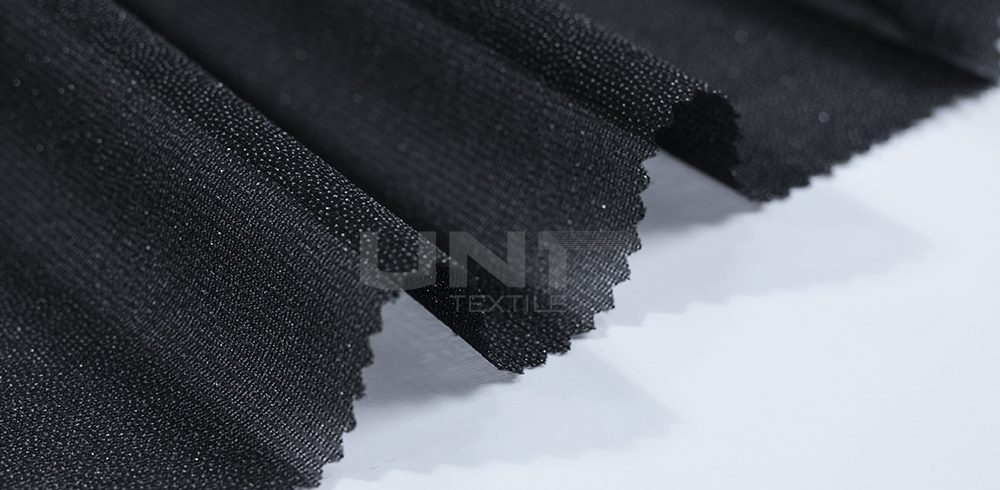

fusible interlining bonding conditions

-

Temperature (Heat Application)

The adhesive on the interlining must reach its activation temperature so it can melt and penetrate the fabric surface. If the temperature is too low, the adhesive won’t fully activate; too high, and the fabric or adhesive may degrade or discolor. -

Pressure

Adequate pressure forces the molten adhesive into contact with both the interlining and the fabric, creating a uniform bond. If pressure is uneven or too weak, you may see spots of poor adhesion or bubbling. -

Dwell Time (Contact Duration)

The time during which heat and pressure are applied must be sufficient to allow adhesive flow, bonding, and cooling into place. Insufficient time leads to weak bonding; too long risks damage or excessive stiffening.

These three parameters need to be balanced—changing one may require adjusting the others.

fusible interlining bonding conditions

Temperature: How Hot Should It Be?

The right temperature activates the adhesive without damaging the fabric. Too little heat results in weak bonding; too much can discolor or deform the material.

1. Adhesive Activation Range

Every fusible adhesive has a melting point—usually between 120°C and 150°C. Staying within this range ensures proper melting and flow.

2. Fabric Heat Tolerance

Light fabrics like silk or polyester can scorch easily. Always test a small swatch before full production.

3. Uniform Heat Distribution

Uneven heat can cause partial bonding or bubbling. Make sure the press machine’s plates are well-calibrated.

4. Testing Before Production

Run several samples at incremental temperatures to find the best setting for your specific fabric and interlining.

Pressure: How Much Force Is Needed?

Pressure ensures close contact between adhesive and fabric, allowing molten glue to penetrate evenly.

1. Balanced Pressure Across Surface

Uneven pressure causes weak spots or wrinkles. Ensure the press platen is flat and clean.

2. Adjusting for Fabric Thickness

Heavier or multilayer fabrics require higher pressure to drive the adhesive through all layers.

3. Avoiding Excessive Pressure

Too much pressure can squeeze out adhesive or cause the interlining to lose elasticity.

4. Machine Calibration

Regularly check machine rollers or plates for consistent pressure output across the surface.

Time: How Long Should You Apply Heat and Pressure?

Bonding time—or dwell time—controls how long heat and pressure act together to set the adhesive.

1. Adequate Melting and Penetration

Short dwell times prevent full activation; slightly longer times allow better adhesive penetration.

2. Cooling Period

Let the fabric cool before movement; disturbing it while hot can break the adhesive film.

3. Consistency in Production

Keep dwell time consistent to avoid uneven bonding quality in batch production.

4. Equipment Speed

On continuous fusing machines, slower belt speeds increase dwell time—adjust accordingly.

What Factors Affect Fusible Interlining Bonding Conditions?

-

Type of Fabric

Natural fibers (like cotton) behave differently from synthetics (like polyester or nylon). The melting point, heat tolerance, and shrinkage vary, so bonding settings must match the fabric’s nature. -

Interlining Material & Adhesive System

Different interlining constructions (woven/nonwoven) or adhesive formulas require different bonding profiles. -

Fabric Weight & Thickness

Heavier or thicker fabrics may need a bit more heat or time to ensure the adhesive reaches all layers. -

Moisture Content

Moisture in the fabric or interlining can vaporize under heat, causing bubbles or weakening the bond. Pre-drying or conditioning may be necessary. -

Machine & Press Characteristics

The machine’s heat distribution uniformity, platen quality, and pressure consistency influence effective bonding.

How to Test and Calibrate Fusible Interlining Bonding Conditions

-

Start with Manufacturer Guidelines

Use the recommended range from the interlining supplier as your starting point. -

Sample Trials

Use small swatches of your fabric and interlining. Run trials across a matrix of temperature, pressure, and time variations. -

Peel Strength Testing

After bonding, carry out peel tests to quantify adhesion strength. Compare against minimum acceptable values. -

Wash & Press Simulation

Expose test samples to multiple wash, dry-clean, and pressing cycles to see how the bond holds up over time. -

Visual Inspection

Look for bubbles, delamination, wrinkling, or adhesive seep-through to detect subtle defects. -

Adjust Incrementally

Modify one parameter at a time (e.g. raise temperature by a small increment) and retest to fine-tune.

What Advanced Techniques Enhance Bonding?

1. Pre-Drying the Fabric

Removing moisture prevents steam formation, which causes bubbles and weak adhesion.

2. Test Pressing with Paper Interlayer

A protective paper layer ensures clean release and prevents glue contamination on the press.

3. Dual-Stage Pressing

Some high-end fabrics benefit from a two-step bonding process—initial light press, then a second press for stronger adhesion.

4. Using Controlled Cooling Systems

Controlled cooling locks the adhesive in place, reducing shrinkage or warping after bonding.

5. Continuous Monitoring Systems

Modern fusing presses can monitor heat and pressure digitally to ensure every piece is fused under optimal conditions.

Why Are Fine-Tuning Bonding Conditions Important?

Fine-tuning ensures that even slight variations in fabric structure, adhesive coating, or ambient conditions don’t lead to bonding failure. It also helps improve product consistency and reduce wastage.

1. Adaptability to Fabric Variety

Different fabrics respond differently to heat and pressure—fine-tuning keeps quality stable across styles.

2. Longer Garment Life

Well-bonded interlining prevents delamination after washing or pressing.

3. Better Hand Feel and Appearance

Proper bonding preserves the natural drape of the garment without making it too stiff.

4. Reduced Production Defects

Correct calibration minimizes rejects caused by bubbles, wrinkles, or poor adhesion.

What Are Common Pitfalls & How to Avoid Them?

-

Overheating

Adhesive or fabric damage can occur if the temperature is too high. Always stay within safe margins for the fabric. -

Uneven Pressure

Irregular pressure across the pressing surface causes inconsistent bonding. Ensure platen flatness and machine calibration. -

Underestimating Dwell Time

Especially for thick fabrics or interlinings, too short a time means the adhesive may not fully flow and bond. -

Ignoring Environmental Conditions

Humidity or ambient temperature can affect how adhesive behaves. Keep production environment controlled. -

Mismatch of Materials

If adhesive and fabric are incompatible (e.g., low melt adhesive on high-melting synthetic), bonding will never be satisfactory.

FAQ (Frequently Asked Questions)

Q: How much margin should I allow for bonding settings?

A: It’s wise to leave a buffer zone—operate well within safe limits for fabric heat tolerance rather than at extremes.

Q: Can you fix a bad bond later?

A: Sometimes gentle reheating under correct pressure may help, but full recovery is hard. Prevention is better.

Q: Which parameter is most sensitive?

A: It depends on system, but many find dwell time is often the most critical to get right in practice.

Q: How often should machines be recalibrated?

A: Regularly — daily or weekly depending on use — to maintain consistent pressure and temperature output.

Why Choose Shanghai Uneed Textile Co., Ltd.?

At Shanghai Uneed Textile Co., Ltd., we specialize in producing fusible interlining and helping you set precise bonding parameters.

-

Technical Experience: Our R&D team provides guidance on bonding profiles for different fabrics and interlining types.

-

Strict Quality Control: We test each batch with peel, wash, and press cycles to validate recommended parameters.

-

Customized Support: We assist clients in calibrating adhesive, temperature, pressure, and dwell time for their manufacturing lines.

-

Reliable Supply & Service: Years of exporting experience and strong after-sales support make us a dependable partner.

continue reading

Related Posts

This article explains fusing interlining, how it works, common types, applications, and practical tips for proper fusing.

This article gives a full overview of interlining, including coating types, product categories, structures, features, and common uses.

This article explains nonwoven fusible interlining, its features, uses, and how to choose the right type for garments.

.png)