the latest from the workshop

short reads & updates

Nulla porttitor accumsan tincidunt. Praesent sapien massa, convallis a pellentesque nec, egestas non nisi. Donec sollicitudin molestie. Curabitur aliquet quam id dui posuere blandit quisque velit nisi.

This article explains fusing interlining, how it works, common types, applications, and practical tips for proper fusing.

This article gives a full overview of interlining, including coating types, product categories, structures, features, and common uses.

This article explains nonwoven fusible interlining, its features, uses, and how to choose the right type for garments.

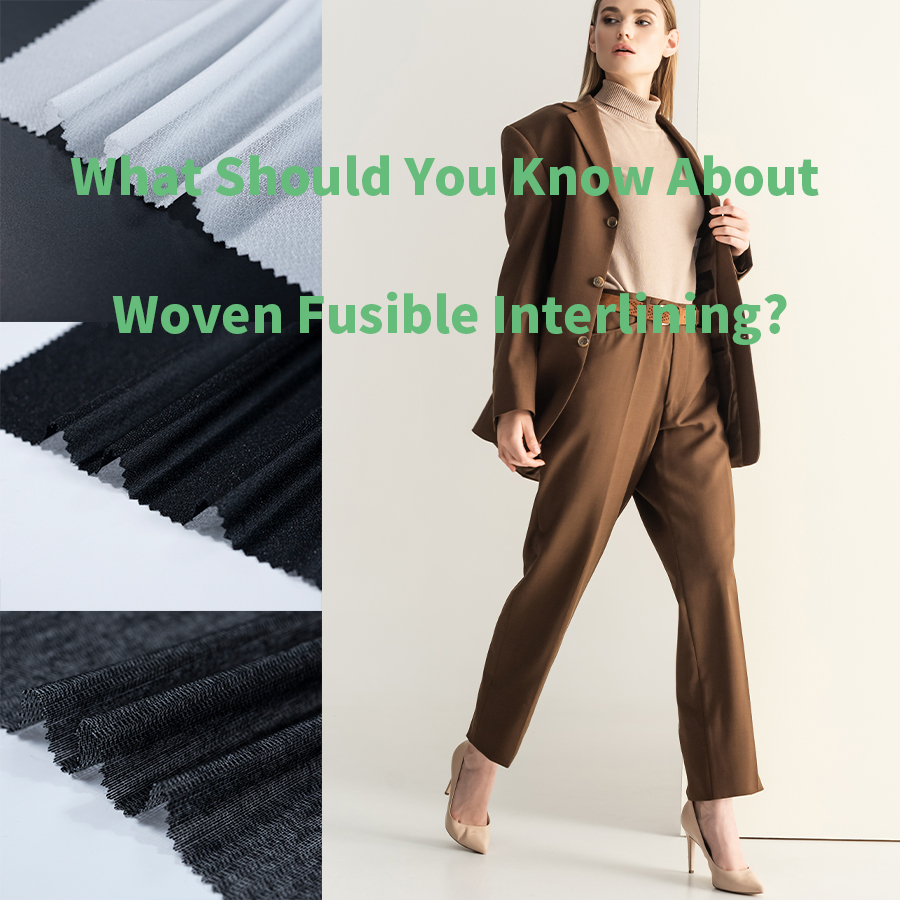

This article explains woven fusible interlining, how it works, where it’s used, and how to choose the right one.

This article explains waistband interlining from a practical garment production view, including real uses, specs, and buying tips.

This article explains knitted interlining in detail, including its structure, advantages, applications, and how to choose the right type.

.png)